AI and AU Testing of ASHRAE 110-2016

Date: 2022-01-18 Source: RUANQI Classification: Resources

1 Definition

AI (as installed) installation detection

——It is the test of no-load fume hood before use. The test is carried out in the field laboratory, which is a form of debugging. If you have conducted an AM test on the fume hood, you can compare it with the AI test results. If there is a significant difference in performance, it indicates that there is a problem in the building HVAC or laboratory ventilation system that needs to be solved. Regardless of the cause, this test will verify that the performance of the fume hood is acceptable. Once the fume hood has an acceptable AI test report, we now know that the laboratory is safe for users. All newly built laboratories shall conduct AI tests to verify whether the whole system operates as designed and the safety level is acceptable.

Au (as used) usage detection

——It is a test of the fume hood in use. The test is carried out in the field laboratory and is usually completed when normal equipment is in place. Assuming we have acceptable am and AI test reports, we are now testing the impact of user work practices on performance. We often find that fume hoods that fail to reach an acceptable level in Au testing are the result of changes in the laboratory ventilation system. These systems are very complex and require regular maintenance to perform as designed. Other times, it's just operational practices that can be corrected. Regardless of the cause, this test will verify that the performance of the fume hood is acceptable.

2 Purpose

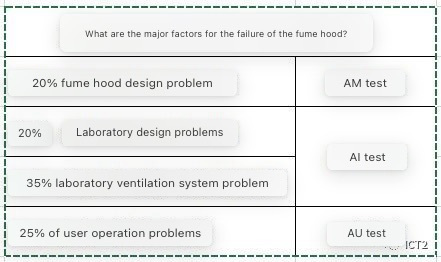

It is no exaggeration to say that the best fume hood in the world can do nothing before it is connected to the laboratory ventilation system. Only by connecting a good ventilation system can the fume hood operate normally and safely. An important part of the fume hood is often ignored, that is, the user. The user's compliance practice will affect the normal operation of the fume hood. If you don't know the importance of AI and Au testing, let's look at a group of statistics in the industry:

Picture from chip Albright

AI and Au tests are laboratory and field tests, so they are the most important for users or fume hood owners.

Picture from chip Albright

Complete ventilation system and normal operation of all parts can ensure the safety of the laboratory.

3 Importance

Fume hoods are mainly used in scientific research and industrial fields. Users include scientists, researchers, students and enterprise researchers. These people are the most precious resources of the country. A safe laboratory environment is very important to protect their health; The normal operation of the fume hood is an important part to ensure the safety of the laboratory environment, so the importance of AI and Au testing of the fume hood is self-evident.

4 Testing

According to ASHRAE 110-2016 standard, AI and Au tests include three types of tests: surface wind speed test, smoke visualization test and tracer gas test. Among them, smoke visualization test and tracer gas test, AI and am test are consistent. For detailed test, please refer to the previous article "am test of ASHRAE 110-2016". In the Au test, a smoke test needs to be added: release smoke around the installed equipment for test.

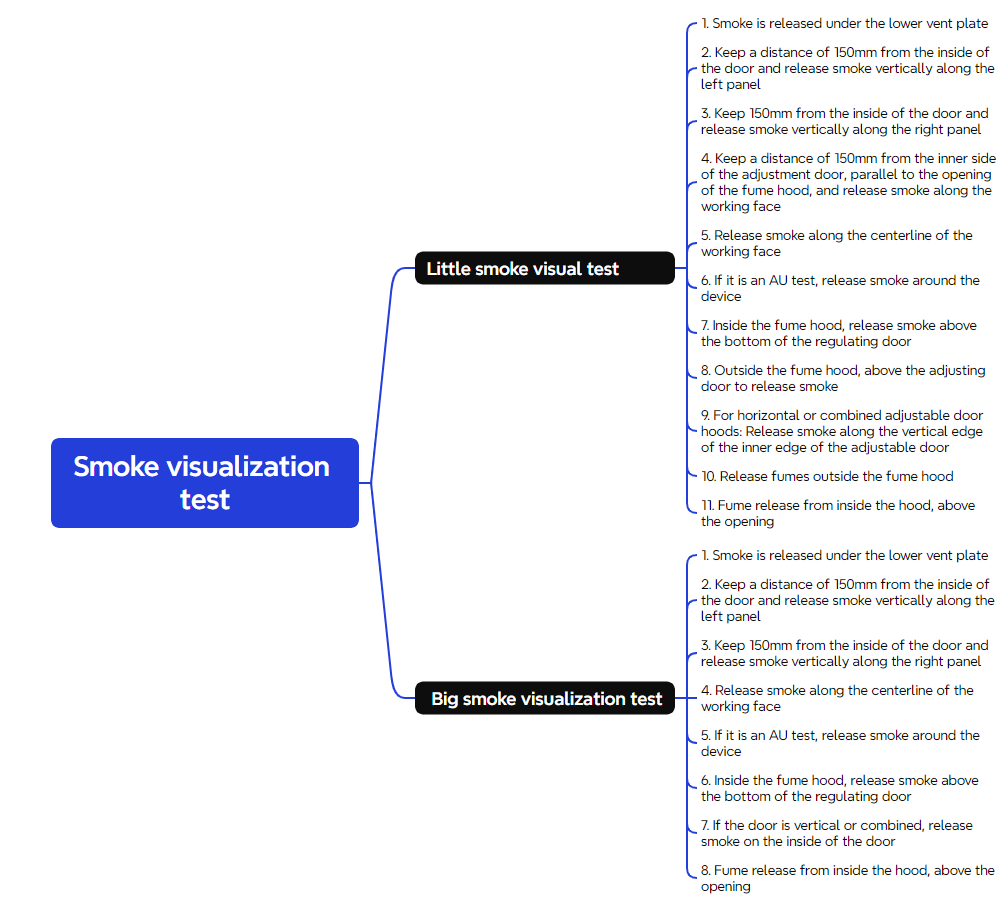

1) Smoke visualization test

ASHRAE 110-2016 smoke visualization test (am, AI and Au)

For detailed introduction of smoke visualization, please refer to the article in the previous issue of ICT2: "am test of ASHRAE 110-2016"

2) Surface wind speed test

AI and Au tests are different from am tests in surface wind speed (when necessary). AI and Au tests are more than am tests in VAV surface wind speed control test and VAV response time test. Variable air volume (VAV) means variable air volume. Surface wind speed will change with the change of sliding door height. This test is only for VAV fume hood, so it is necessary, But in fact, most of them use this type of fume hood now.

For the detailed introduction of surface wind speed test, please refer to the article in the previous issue of ICT2: "am test of ASHRAE 110-2016"

The following mainly introduces the VAV surface wind speed control test and VAV response time test.

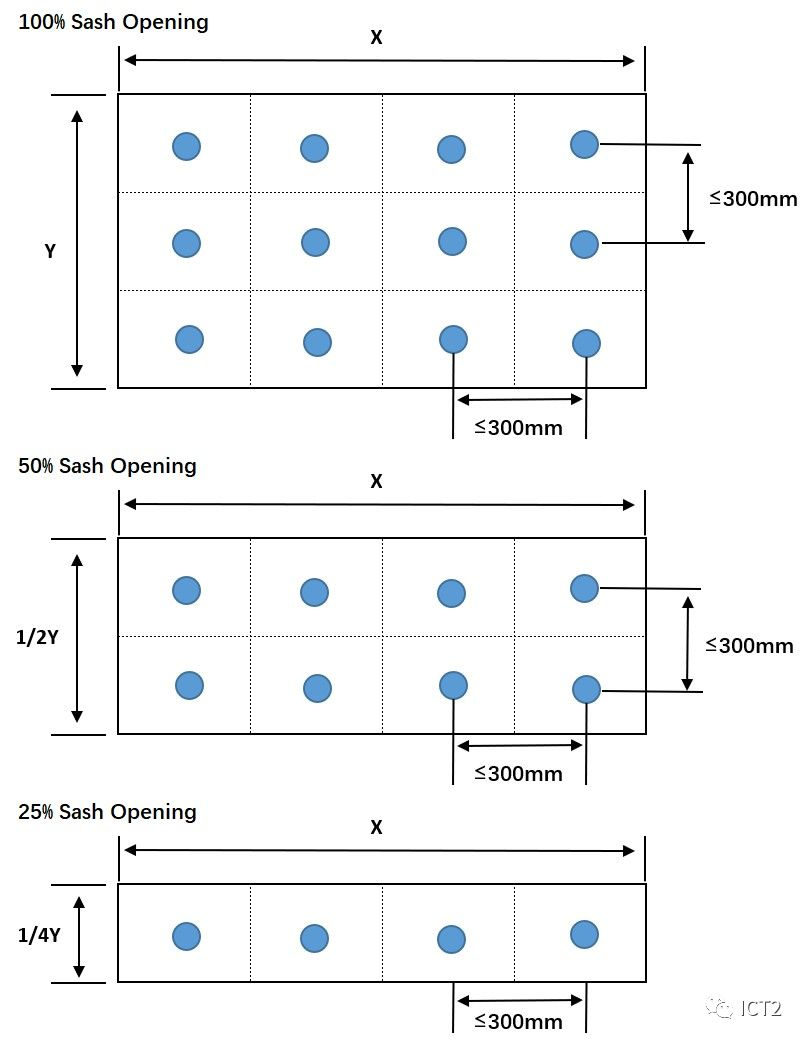

A. VAV surface wind speed control test

Measure the surface wind speed at different sliding door heights:

a. 25% Sash Opening

b. 50% Sash Opening

c. 100% Sash Opening

100% sliding door height is the designed working height of the fume hood.

Refer to the previous article "am test of ASHRAE 110-2016" for detailed test

B. VAV response time test

Response time refers to the time when the VAV system recovers and maintains the average wind speed or air velocity between 90% - 110% of the average steady-state value measured from the first movement of the sliding door.

2.1 firmly place the sensor in a proper position.

Method A: fix the wind speed probe on the centerline of the exhaust pipe.

Method B: using configuration B1 or B2 shown in Figure 6.2, install the wind speed probe in the safety support, and the probe is located at the bottom of the baffle opening.

2.2 close the sliding door and record the wind speed reading on the ventilation cabinet surface of the laboratory.

2.3 use the data logger to start recording at the rate of one reading per second.

2.4 after 30 seconds, open the sliding door from the closed position to the design height at a speed of about 1.5 ft / S (0.5 m / s). Record the corresponding sliding door opening time.

2.5 after 60 seconds, close the sliding door at a speed of about 1.5 ft / S (0.5 m / s).

2.6 repeatedly open and close the sliding door three times.

2.7 after the sliding door begins to move, determine the response speed and the time (in seconds) required to reach the steady state, and evaluate the repeatability of the low response.

VAV response time test atlas --- picture from ASHRAE 110-2016

VAV response time test layout - picture from ASHRAE 110-2016

3) Tracer gas test

For the detailed introduction of surface wind speed test, please refer to the article in the previous issue of ICT2: "am test of ASHRAE 110-2016".

5 Practical operation cases

We can see a good layout on the right.

It is almost impossible for this fume hood to work safely.

Picture from chip Albright

This is completely a storage cabinet.

Picture from chip Albright

This setting looks complex, but it's actually a good setting.

Picture from chip Albright

This is also a good setting.

Picture from chip Albright

See here, do you think your fume hood is still safe?

If you have problems with the use, design or any other aspects of your fume hood, please contact ICT2.