Chemical Laboratory Industry Heavyweight News: ASHRAE New Standard - chemical Laboratory Classification Standard

Date: 2022-01-19 Source: RUANQI Classification: Resources

1 Introduce

The laboratory classification Subcommittee of ASHRAE Technical Committee (TC) 9.10, the laboratory health and Safety Committee of the American Association of industrial hygiene (AIHA) and the chemical health and safety department of the American Chemical Society (ACS) have cooperated to provide this document to help facility professionals design and operate the laboratory, To support the management of airborne chemical spills generated during laboratory scale activities. It is important to note that ventilation alone cannot handle all laboratory chemical hazards, and this document assumes other control measures, including minimum chemical risk, good laboratory general management and appropriate emergency procedures. A control hierarchy has been established in the safety specialty. Laboratory ventilation is a form of engineering control and a level in this hierarchy. (for more information on the control level, please refer to the National Institute of occupational safety and health [NIOSH] website www.cdc.gov/niosh/topics/hierarchy/default.html [NIOSH 2016])

For the purposes of this document, the laboratory scale is defined as a workplace where hazardous chemicals are not used productively. The occupational safety and Health Administration (OSHA) laboratory standard 29 CFR 1910.1450 (b) states:

Laboratory scale means the use of substances in which containers for reaction, transfer and other substance handling are designed to be easily and safely manipulated by one person. "Laboratory scale" does not include workplaces whose function is to produce commercial quantities of materials. (OSHA CFR n.d.)

Although the definition does not limit the type or severity of chemical hazards used in the laboratory, it does limit the amount of material that may be released into the laboratory environment to about 4 liters (1 gallon) or less per process. Reducing the risk of airborne chemical hazards at the laboratory scale means controlling the concentration in the air below the level known or likely to cause harm to people, property or the environment by combining general and local ventilation and other measures mentioned above.

According to the activities carried out in the laboratory, the type of hazardous chemicals, the quantity of materials, the characteristics generated, the duration of exposure and the risk of exposure to airborne chemicals in unsafe concentrations in the laboratory are negligible to critical. Protection provided by laboratory airflow and air pollutant control system. Therefore, the risk assessment must be based on the best available information about the chemical work carried out in the laboratory. The ability to mitigate human, property and environmental risks depends on providing adequate protection through appropriate design, operation and laboratory utilization: pollutant control devices (ECDs), such as fume hoods and laboratory ventilation systems. In general, ECD, exhaust system, air supply system and laboratory components that may affect airflow and air pollutant control are referred to herein as laboratory airflow control system (lacs). Lacs has two purposes: it must (1) help prevent excessive exposure to airborne chemical hazards generated during laboratory scale activities; (2) Meet the user's temperature and humidity regulation requirements and the process carried out in the laboratory workplace.

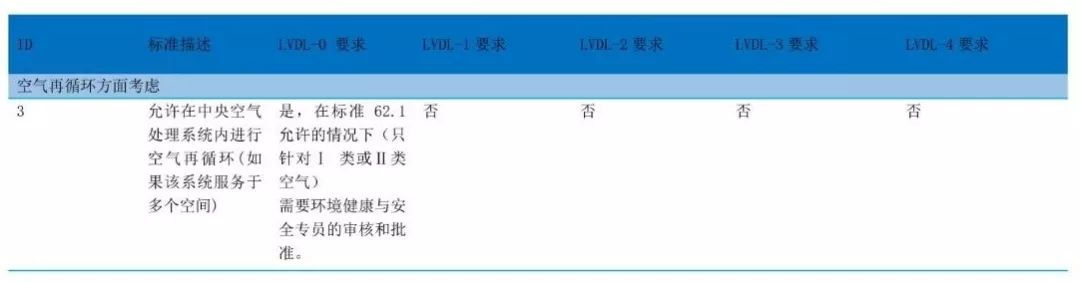

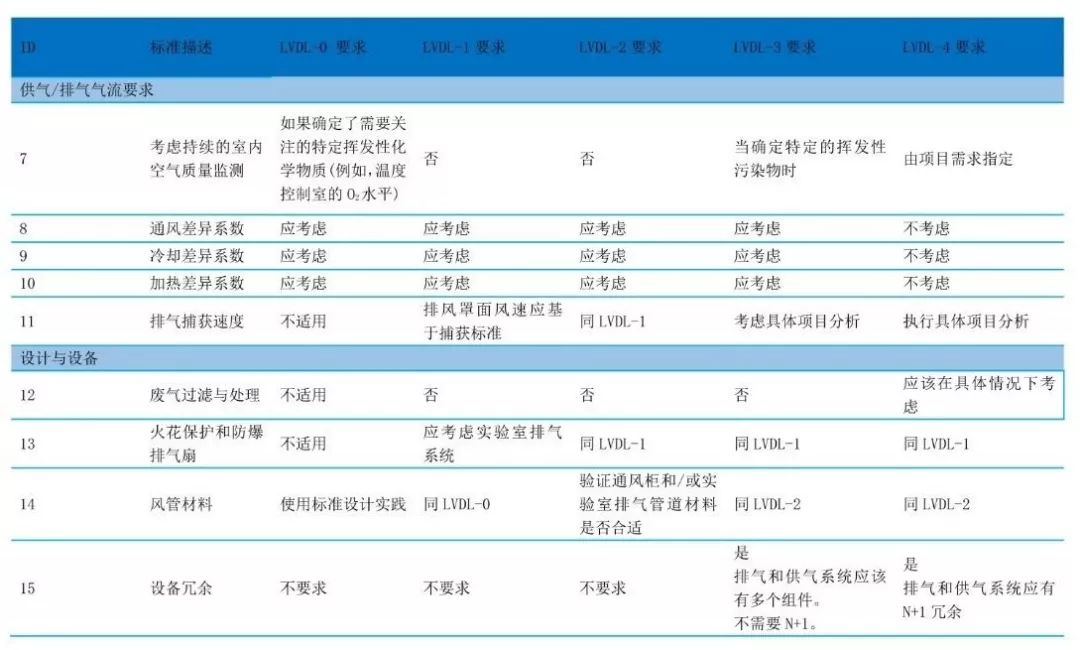

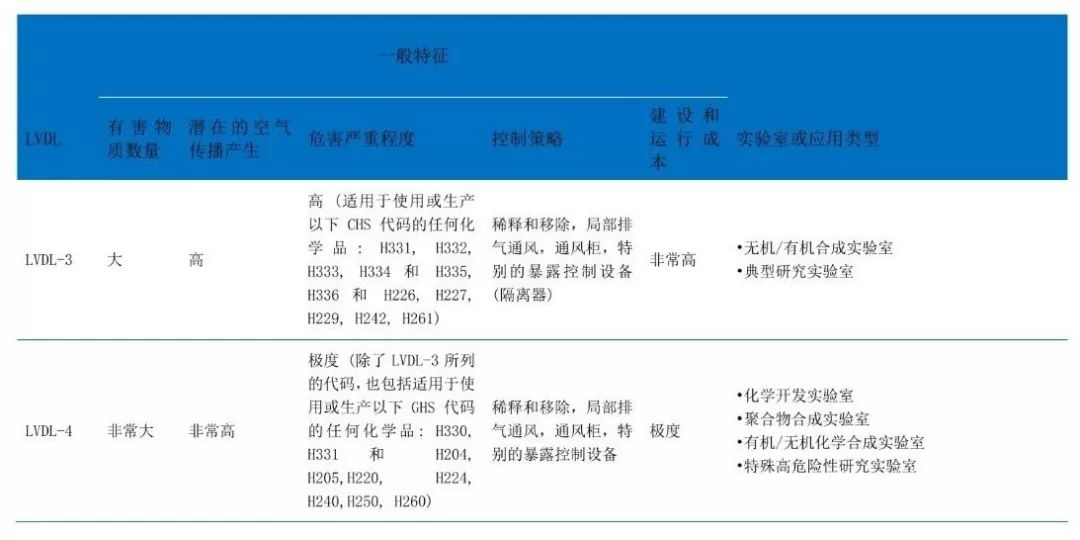

The protective capacity provided by lacs must be commensurate with the level of risk associated with possible airborne chemical hazards. Tables 2 and 3 provide the physical design attributes and operating specifications of lacs, which are divided into five laboratory ventilation design levels (LVDL), ranging from lvdl-0 to lvdl-4. The properties and specifications of each LVDL are designed to provide protection and control of increasing airborne chemical hazards to minimize the risk of over exposure. Specifically, lacs with lvdl-0 related properties and specifications provide the lowest level of protection for the use of hazardous airborne chemicals, while lacs designed and operated according to lvdl-4 recommendations provide the highest level and control of airborne hazards. It is worth noting that this guide does not provide the tools needed to assess the risks associated with the use of hazardous chemicals at the laboratory scale. The information contained herein can be used to assess the protection capability of existing lacs or to help design and operate lacs based on the expected risk level or the degree of protection required to provide a safe and healthy laboratory environment. Although higher lvdls may increase the protection capacity of the laboratory, they also increase construction costs, lead to greater energy consumption, increase operating costs, and increase the workload required to manage and maintain performance. These factors must be carefully considered in the design and operation of laboratory facilities.

2 Objectives and scope

This work is limited to issues related to the design and operation of the laboratory and its interaction with lacs, which can provide regulation and control of ambient air quality in the laboratory. It does not seek to duplicate work within the terms of reference of other ASHRAE committees or other organizations. Methods and tools for assessing hazardous chemical procedures or specifying the risk level of airborne chemicals are not part of this work. Therefore, without a comprehensive hazard assessment by skilled practitioners, compliance with the recommendations in Table 3 may not ensure adequate protection or reduce the risk of all possible hazards. A risk assessment is strongly recommended to determine the appropriate LVDL, design attributes and operating specifications.

This document provides background information to help classify, design and operate lacs according to the LVDL table (Table 3) contained in the appendix. This table describes the standards, design attributes and operating specifications related to each LVDL. The purpose of the LVDL classification system and table a is to facilitate communication among stakeholders in assessing the protection capacity of existing lacs or in discussing the design, construction and operation of new Lacs for managing and controlling airborne chemical hazards.

These recommendations are largely based on the American Conference of governmental industrial hygienists (ACGIH) publication industrial ventilation, design Recommended Practice Manual (ACGIH 2013), ANSI / AIHA / ASSE Z9 5. Laboratory ventilation (AIHA 2012) and ASHRAE laboratory design guidelines (ASHRAE 2015). Specifically, this document addresses problems that may be encountered in the design, transformation or continuous management of laboratories, ECDs and lacs. By limiting the scope of this document to laboratory scale, the use of airborne hazards may require additional guidance for laboratory facility designers to adapt to other hazards not considered in this document (i.e., biological, radiological and physical hazards). Therefore, the protective measures for these other hazards that the laboratory may encounter must be based on a comprehensive hazard and risk analysis.

This guide does not provide a method for assessing the risks associated with airborne chemical hazards, exposure to other laboratory hazards, or the required performance level of the system. The five lvdls outlined in this document may not be consistent with the risk and security levels described by other organizations. However, the classification system described here can be used as a basis for the design and operation of laboratories and the evaluation of the protection capacity of existing laboratories. Health and safety experts should be consulted when investigating and identifying risks associated with hazardous processes and matching them with appropriate LVDL and the interaction of lacs with other protective measures, such as emergency plans and personal protective equipment.

3 Relevant work of other organizations

The Chemical Safety Committee (CCS) of the American Chemical Society (ACS) documents best practices for the safety of chemical activities http://acs.org/safety (ACS n.d.) research laboratories provide guidance, methods and tools for assessing and controlling hazards. For biological laboratories, important references are Biosafety (bmbl) of microbial and biomedical laboratories (CDC 2009) and NIH research guidelines involving recombinant or synthetic nucleic acid molecules (NIH guidelines) (NIH 2016).

4 Laws and regulations

This guide can be used as a resource to help control the chemical hazards caused by airborne use in the laboratory. The elements of this guide will be implemented in the absence of or as a supplement to their respective laws and regulations, standards formulated by authorities and site-specific agreements. If higher (specific or additional) standards are required by national or local laws, they must be observed. If national or local laws require less stringent standards, facility codes and standards must be followed.

Unless exempted, the system design and operation requirements must comply with the mandatory provisions of relevant codes and standards. Nothing in this guide is intended to replace the requirements of codes or standards or authorities with jurisdiction, nor is it intended to replace the need for consultation with registered design professionals, regulatory officials and environmental health and safety experts necessary to achieve safety. Provide working space for users and protect property or environment from damage.

5 Key definitions

The following definitions provide clarity and context for certain terms used in this guide.

Airborne chemical hazards: Chemicals suspended or mixed in the air may be similarly controlled through ventilation strategies. These are mainly gases and vapors produced by volatile chemicals, which have flammability, reactivity, toxicity hazards or odor problems. Other types of air pollutants may include particles, smoke and aerosols. These may require a different control strategy from the gas.

Emergency: the release of airborne chemical hazards in an amount or rate that exceeds that expected by typical laboratory scale activities and processes. These situations require special measures to restore the laboratory space to an acceptable state. The main emergency response measures involve the evacuation of laboratory staff, the response of teams with appropriate personal protection, and long periods of inactivity or the provision of additional ventilation when available.

Failure mode analysis: the process of identifying all possible faults in the system and evaluating the impact of these faults.

Hazard: any article in the workplace that may endanger personnel, property or the environment. Hazards may include objects in the workplace, such as machinery or chemicals, biomaterials and radioisotopes. With regard to airborne hazards, the severity of the hazard is inherent in the characteristics of the material.

Laboratory: the use of hazardous space complies with OSHA's definition of laboratory scale: "substances that use containers for reaction, transfer and other substance treatment can be easily and safely operated by one person" (OSHA CFR n.d.). The laboratory scale does not include workplaces whose function is to expand the scale or produce commercial quantities of potentially hazardous airborne materials.

Laboratory ventilation design level (LVDL): laboratory and ventilation design, components and operation specifications can be expected to control the concentration of chemical hazards in the air during the scale of the laboratory.

Change management: continuously monitor the process and provide a mechanism to detect and respond to changes in laboratory processes and risks. This may require a reassessment of the risks and the allocation of control belts related to system operation and modifications to accommodate changes in functional or safety requirements.

Risk: the possibility of contact with dangerous concentrations in the air is sufficient to cause injury (death, injury or disease), property (degradation or corrosion) and environment (pollution).

Control strip: the hazard identification and risk assessment system organizes the information about hazards and processes into groups according to the correlation with the concerned health and safety scenarios. Factors to be considered when performing this task in a ventilated laboratory environment include chemical hazards, quantity, and the possibility of airborne transmission in the laboratory and buildings. It is important to note that some processes may not belong to a specific control strip system due to abnormal hazards or applications. With respect to a specific area, the determination of whether the equipment or process is suitable for the control strip is the first step in the allocation of the control strip.

Ventilation effect: the ability to reduce the accumulation of unsafe concentration through the comprehensive mechanism of dilution and pollutant removal in the whole laboratory. Dilution in a fully mixed environment is a function of the air change rate, and ventilation efficiency is a function of the airflow pattern formed by how air is supplied and discharged from the space. Increasing the ventilation rate may not have a positive impact on the ventilation effect. The flow in the laboratory and the resulting airflow pattern must be considered to maximize ventilation efficiency.

Volatile chemicals: chemicals that tend to evaporate at lower temperatures (i.e. below 38 ° C [100 ° F]). The volatility level is related to the vapor pressure of the chemical and is therefore chemically characteristic. For example, materials such as acetone have high vapor pressure and low boiling point, which is equivalent to high volatility.

6 Ventilation control air hazards

As the main engineering control, lacs reduces the damage to people, property and environment by controlling the accumulation and migration of chemical hazards in the air generated by the laboratory. Ventilation control technology includes the control, capture, dilution and removal of chemical hazards in the air from the laboratory. Lacs includes various types of ECDs, such as fume hoods, breathing tubes, telescopic arms, biosafety cabinets, and glove boxes for local capture. Lacs also includes the physical layout or terrain of the laboratory, the airflow pattern affecting the room, the air supply and exhaust system, and the safe emission of air pollutants in the building. The degree of protection provided by lacs depends on the coordinated design, operation and use of all these elements.

The laboratory and lacs must be adapted to chemical hazards and provide adequate control and protection when properly designed, operated and used by trained personnel. The risk level and ventilation requirements in the laboratory and any laboratory may vary depending on the user, the type of hazard and the process carried out. Therefore, in the laboratory environment, the management of change procedures is particularly important. Successful management of the change program involves various stakeholders, but the design basis of the laboratory ventilation system should include consideration of how to support changes in laboratory practices. Laboratory personnel must be trained in the correct use of work practices, understand the limitations of lacs, and identify when hazardous processes may exceed the capabilities of lacs.

As part of this plan, the design, construction and operation of lacs are based on potential applications and must be able to provide sufficient protection under a series of expected operation modes and flexibly adapt to reasonable changes in ventilation requirements. There are many different protection technologies and technologies that can be used to meet this demand and to meet the required level of control and protection. However, it is impractical and expensive to apply the highest level of control to all laboratories to adapt to all possible current and future chemical emissions. Combining the functions applicable to all applications will lead to lacs being too complex, wasteful, and extremely difficult to manage and maintain. Therefore, the control level must be defined.

7 Composition and characteristics of laboratory air flow control system

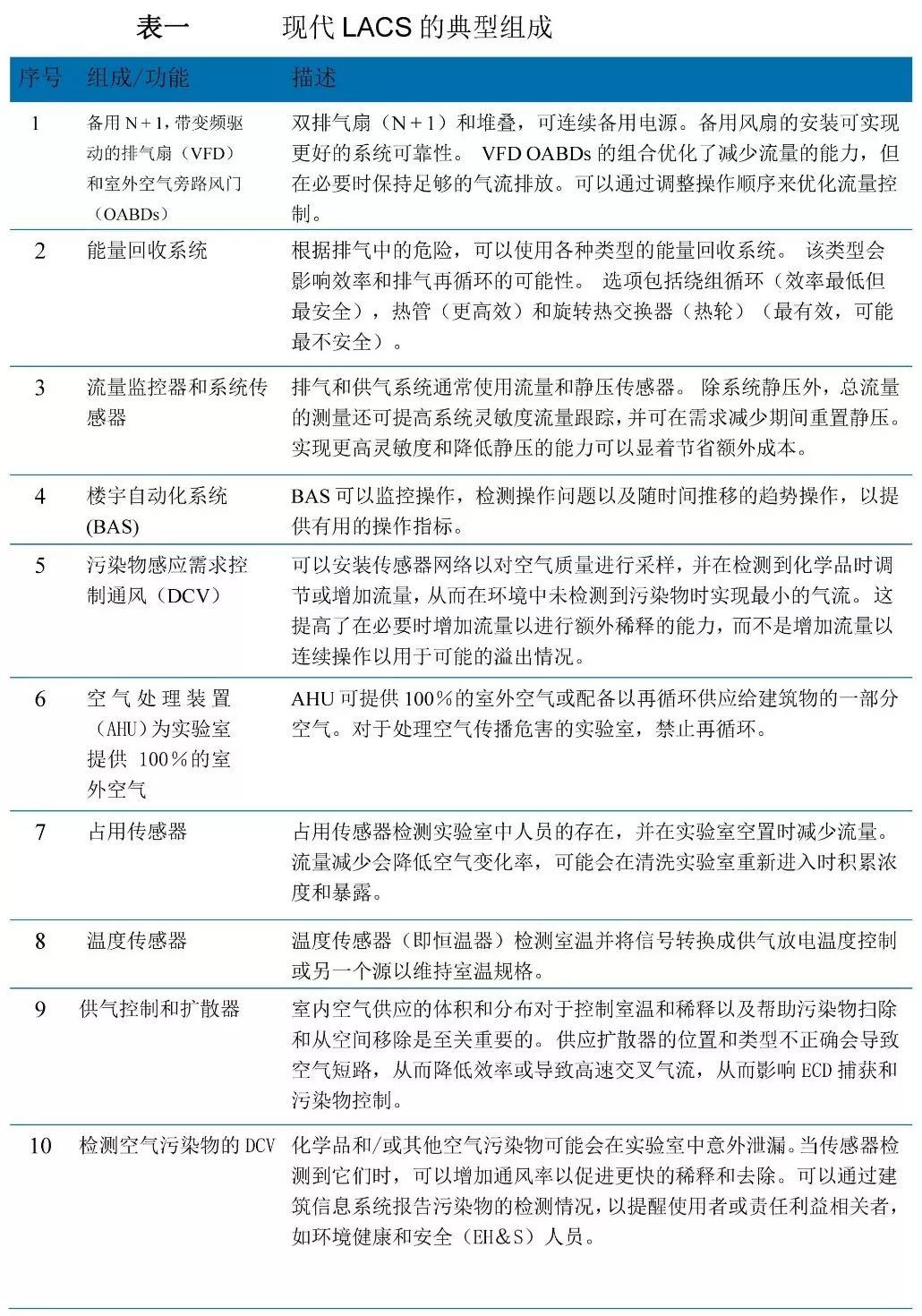

The design, construction, operation and use of lacs will affect the ability to control chemicals in the air, meet safety requirements and meet ventilation requirements. Lacs can be simple, constant volume (CV), independent systems, or complex variable air volume (VAV), which can regulate the air flow in multiple spaces under a series of operation modes. Figure 1 and table 1 depict a complex, modern VAV exhaust and air supply system that can adjust the flow according to the change of ventilation demand.

Figure 1 is provided to show and describe the main components of Lacs for discussion with stakeholders who may not be familiar with the various components, attributes and specifications described in the appendix.

Figure 1 a simplified diagram of the laboratory and lacs showing key components and attributes

8 Laboratory ventilation design grade

Assessing risks and the resulting ventilation needs can help to develop appropriate specifications for the design and operation of laboratories, exposure control equipment (ECDs) and the entire system. Similarly, the evaluation of the existing laboratory air flow control system (lacs) can help to determine the existing protection level and the inherent potential of protection. Understanding the level of protection provided by lacs can help determine whether it is suitable for applications involving hazardous air substances, or whether the design or operation needs to be modified according to the risk and the required protection. The protection capability of lacs is based on a combination of physical design attributes and operating specifications (such as air exchange rate and flow).

This guide divides the design and operation of lacss into five laboratory ventilation design levels (lvdls). Each level is associated with different levels of protection through design characteristics (physical attributes) and operational characteristics. As shown in Figure 2, lvdl-0 represents a laboratory whose control of air pollutants is negligible and suitable for the activities with the lowest risk, while lvdl-4 represents that lacs has the characteristics, attributes and operating characteristics that can provide the highest level of protection. The level of protection provided by lacs is not limited by individual design characteristics or operating specifications, such as air change per hour. Instead, LVDL and protection capability levels are based on a combination of components, features, and specifications that make up lacs. Higher lvdls can be achieved through higher construction costs, higher energy consumption, higher complexity, higher operating costs and greater management and maintenance efforts.

It is also important that the facility owner recognize that the selection of LVDL for the laboratory during the design process will affect the type of activities suitable for the laboratory after completion. Prior to hazardous work in these spaces, specific reviews must be conducted to determine whether the work is consistent with the assumptions made during project planning, design and construction. The resources for conducting laboratory hazard and risk assessment may exist in institution specific information, such as institution design standards, laboratory ventilation management plan (according to the requirements of AIHA / ASSE z9.5 [AIHA 2012]), or other systems and guidance documents established by environmental health and safety (EH & S) staff. These resources should be consulted early in the design and development phase or when assessing the suitability of laboratories for work related to airborne hazards.

Figure 2 protection level corresponding to air hazard level and LVDL

Table 2 describes the general characteristics and typical applications of laboratory LVDL. The LVDL design and operational requirements table in the appendix provides recommendations for the design characteristics, attributes and specifications of different lvdls.

9 Standards and attributes for laboratory ventilation design grades

Table 3 provides the recommended standards, operating specifications and design attributes for each LVDL. The table is divided into several sections according to general application areas and design and operation recommended standards. Each part is further subdivided into separate standards and a description of each standard applicable to each LVDL. As mentioned earlier, lvdl-0 to lvdl-4 represent continuous improvement in protection capability, complexity and cost. The information contained in Table 3 can be used to facilitate communication among stakeholders and provide a level of design and operation appropriate to the actual or perceived level of risk applicable to laboratory activities.

For existing laboratories, the design and operation of lacs can be matched with the standards and descriptions assigned to LVDL. When designing new laboratories or modifying lacss, table 3 can be used to determine the design level appropriate to the expected risk. If there is great uncertainty about the type of activities that may be carried out and the risk range may vary greatly, lacs should be carefully designed and operated according to the recommendations of lvdl-4. However, budget constraints and other issues may require the design of a lower LVDL. In these cases, it is necessary to ensure that all stakeholders are aware of these limitations and that space is combined with other protective measures to provide appropriate protection. Finally, a lacs can be designed for higher lvdls, but run according to lower lvdls when appropriate, so as to save energy and reduce operation cost. Each laboratory and lacs should be appropriately and easily labeled with LVDL functions and the current operating level of the laboratory, and / or this information should be available in a central repository for building design information.