Common Problems in Operation of Fume Hood Exhaust System

Date: 2022-01-19 Source: RUANQI Classification: Resources

For many years, the industry of pollutant control/laboratory exhaust system has frequently heard the phrase "My fume hood can't work properly".

Most of us who have just started our careers are frustrated with this comment, and will eventually find that this is also the appeal of people who want an efficient exhaust system and focus on the most practical part of the exhaust system-the fume hood. Technically, the customer is 100% right. If the exhaust gas escapes from the closed area of the fume hood, the fume hood cannot operate normally. We only need to add two words to make the sentence correct both technically and as a whole: "The fume hood exhaust system can't work properly!"

When the fume hood is "unqualified", any problem of the whole system (exhaust fan, piping system, building structure, fresh air unit, automatic regulating valve) may lead to the failure of pollutant control of the fume hood. As a fume hood manufacturer, we strive to make our fume hood stable and capable of overcoming minor problems in other laboratory exhaust system components. However, the main system problems will always pose a threat to the system pollutant control.

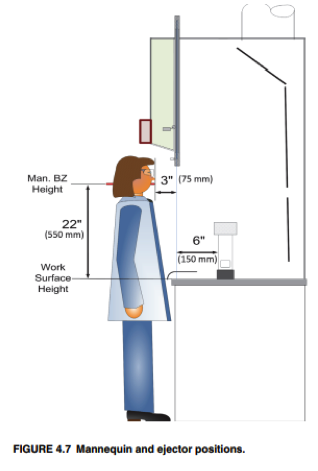

The following situation relates to the exhaust gas detected in the laboratory. This situation is often found or verified by ASHRAE 110 pollutant control test. This test can be summarized as tracer gas, which usually diffuses sulfur hexafluoride (SF6) into the fume hood. The sensor is placed in the breathing area of the mannequin 3 inches away from the plane of the cabinet sliding door. If the concentration of SF6 detected in the breathing area of human body is greater than or equal to 0.050ppm, the inspectors will start to look for things that may adversely affect the pollution control of fume hood.

1. Some early fume hood designs will overflow the exhaust gas, because the smoke will be trapped between the sliding door glass and the bypass when lifting the sliding door. This is just one of many examples.

2. Pipeline leakage, debris in the pipeline, broken fan belt and VAV valve are also some examples.

Case

This article will focus on six "cases" selected from my decades of laboratory experience. From these cases, I will recommend a step to "solve" the frequent pollution control problems. Each case study is a specific example of the corresponding category after the six categories on the chart.

Case 1. Exhaust fan does not operate.

During the university holiday, once, I tried to test the airtightness of the fume hood on the spot, but I couldn't start these devices. This fume hood has no separate "on/off" button. I can only stare at unmarked circuit breakers, one or more of which can activate these fume hoods. Finally, I found that the exhaust fan is a "three-phase" electrical device, which requires relays to connect all three wires to the exhaust fan at one time. Once these relay switches are found and put into operation, the exhaust fan will start. This experience tells me that anyone who is assigned to the construction site to test the exhaust system should arrange a person in charge of construction to be present in advance, so that things can proceed normally. Because no one is familiar with the system during the first visit, it is meaningless to have to go back to the work site the next day in order to open the complicated exhaust system.

Case 2. Accidental corrosion in fume hood will not produce any other obvious conditions.

Many years ago, an oil exploration company began to do research work in a new laboratory equipped with a new fume hood. This is the first VAV fume hood I have ever seen. Although the laboratory is full of fume hoods, the VAV system automatically reduces the flow rate, so it is surprisingly quiet and has no unpleasant smell!

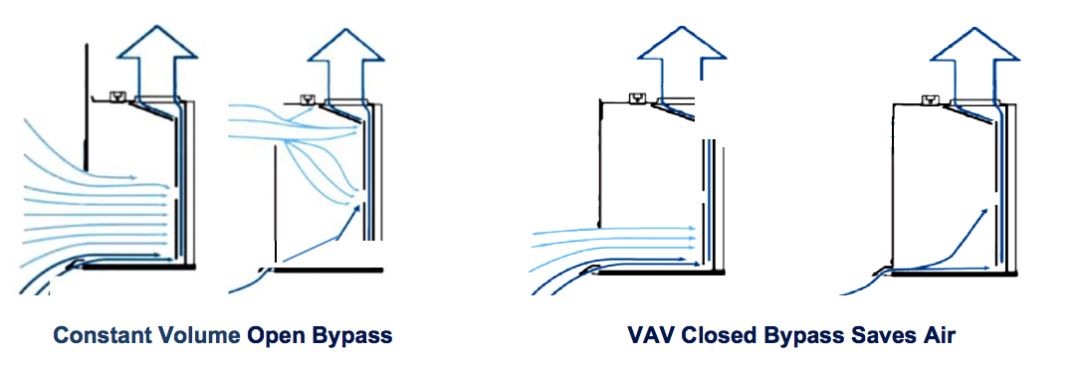

I noticed that according to the design, the fume hood has no bypass at the top of the superstructure. These bypasses are very common in the fume hood at this time, because they allow the system with constant volume to open an upper cavity on the top of the fume hood as a backup air channel when closing the sliding door. This function reduces the increase of surface wind speed when the fume hood is closed. But this is VAV fume hood. With the closing of the sliding door, it reduces the intake of air, so there is no need for bypass. Therefore, a small amount of air is used to exhaust the pollutant smoke. The constant volume bypass system (CAV) and VAV standby system are shown in the following figure:

Closed fume hood system and air door system work well. When I tested the surface wind speed, it remained constant until only one inch of the bottom slot of the wing was left.

Keep it at 100 feet per minute (FPM). (Note that this is an early system! )

However, after less than two weeks of use, all stainless steel equipment in the fume hood seems to be rusty red. The only purpose of these fume hoods is to digest limestone in small watch glass with 20% hydrochloric acid on the hot plate. Most of the time during this process, the sliding door is closed.

During the closing of the sliding door (all through the bottom of the wing), we calculated that the total exhaust volume of the fume hood was 49 cubic feet per minute (CFM). The exhaust volume is equivalent to about one ventilation (ACPM) per minute. The insufficient rate causes hydrochloric acid vapor to be discharged from the cabinet interior, resulting in corrosion. After further experiments, we determined that it would take about five air changes per minute (ACPM) to prevent this problem. Since the 1-inch airfoil bottom groove produces 1 ACPM, we can get 5 ACPM by opening the 4-inch bypass, and finally, it will not corrode again! Since 1987, there have been other methods to ensure that VAV system provides the minimum ventilation. This topic is beyond the scope of this article, but it is very important for the safety and practicality of the fume hood. For acid and flammable vapor, corrosion and explosion are usually the adverse consequences caused by very small ventilation rate.

See the figure below, which shows how to deal with the early VAV corrosion problem.

Case 3. When the sliding door is opened or lowered, the exhaust gas will escape from the fume hood.

Although the improperly designed CAV fume hood will lose its pollutant control ability when moving the sliding door quickly, the well-designed but inadequately maintained VAV system may also show the same problem. For these VAV systems, the problems are usually caused by the measured delay or the response delay of the control elements. Therefore, the root of the problem is that the design of the surface wind speed sensor or the valve system should respond appropriately to the output of the sensor.

A, the surface speed sensor usually measures the airflow into the fume hood through sensors arranged on both sides or at the bottom of the wing. Sensors usually adopt thermistor or hot wire technology. Some designs use algorithms and velocity and pressure readings in the duct system to measure the sliding door position and infer the surface velocity (there are two independent sensors in this example). If the sensitivity of these sensors changes or fails, it may lead to slower response to the sliding door or worse. Sensor degradation or failure can be prevented by strict preventive maintenance procedures.

B. The valve system needs mechanical movement to control the increase or decrease of exhaust volume. Older valve systems may slow down for various reasons, including actuator wear or rotor shaft wear/corrosion. Similarly, this kind of mechanical loss or failure can be prevented by strict preventive maintenance procedures.

C. Another less common reason for slow response of VAV sliding door is to use VAV sensor to control fan rotation per minute (RPM) instead of valve position. This type of control system requires the fan to quickly change the RPM when the throughput demand changes. Because the fan usually has a large angular momentum, the speed change is slower than the valve volume control.

In any case mentioned above, Section 6 of ASHRAE 110-2016 outlines the measuring method and meaning of response time of sliding door. Although there is no consensus on the acceptable response time range, ANSI/AIHA Z 9.5 recommends that the time should be less than 3 seconds (Section 6.3.4.2).

Case 4. Although there is no pipeline leakage or rupture, after any fume hood is in operation, there is trace gas in all building spaces.

I saw this in a rural facility in Texas, where there are about five newly installed fume hoods. All aspects of the cabinet are normal, except that the tracer gas during ASHRAE test appears all over the building, even in the office area. We inquired about the location of the new air inlet of the building, and were told that all air was introduced by a single super air inlet on the leeward side of the building. We also conducted a smoke test, and observed that the exhaust gas left the building through a rather short chimney, swept along the roof line, and then crossed the edge of the building and entered the air inlet. When there is something wrong with the air inlet, each fume hood still works normally. Finally, we realized that the solution to the problem lies in correcting the fresh air inlet or increasing the height of the exhaust pipe.

Case 5. All fume hood equipment showed extremely low surface wind speed. (Usually seen in places where debugging has not been done).

Among all cabinets, a new device with twelve fume hoods shows low air speed on the exhaust side. We were surprised by the poor results, because three separate exhaust fans were involved. Finally, we went back to the roof again and asked to turn off the fan and "slow down". "Decelerating" the three-phase fans means that they are required to quickly "shake" the power supply so that the rotating direction can be observed. In all these cases, the fan runs in the opposite direction. The centrifugal fan will only draw air if it rotates in the right direction, but if it runs in the opposite direction, the efficiency will be reduced. After correcting this situation, all the fans operate at the proper exhaust level, and the surface wind speed of the fume hood is normal.

Case 6. The wind speed on the exhaust system or fume hood seems to be no problem at all, but after about one minute, the exhaust gas on the fume hood comes out!

A new perchloric acid cabinet with high surface wind speed runs for about 90 seconds, and then the SF6 detector of the mannequin begins to show obvious tracer gas. When checked separately, this situation exists in the whole laboratory. SF6 also appears in adjacent laboratories on the same floor. It's time to go to the roof of the lab.

We found a decorative skirt placed around a group of ugly "roof penetrators" to make the roof lines more attractive. Inside the skirt area are perchlorate chimneys and fresh air vents of the same laboratory. We temporarily closed the air inlet, and the cabinet sealing test was successful. We suggest that the person in charge of the construction site correct this situation. This kind of similar problem is very common, which is another reason for ASHRAE 110 field test.

Summary

The above examples illustrate the common reasons why the fume hood system "doesn't work" in one form or another. The overall situation of design defects, maintenance problems or aesthetic function conflicts is obviously more complicated. For more details, please pay attention to ICT2 WeChat official account or refer to the following article:

1) Latest *ASHRAE Chemical Laboratory Ventilation Classification Standard

2) AI and AU testing of ASHRAE 110-2016

3) AM test of ASHRAE 110-2016

4) What is ASHRAE 110-2016?

5) Understand the comparison of performance test methods between American standard ASHRAE 110-2016 and European standard EN 14175-3

6) China fume hood industry standard JB/T 6412-1999

7) Emergency treatment of fume hood accident

8) How to design a safe and energy-saving laboratory exhaust system

9) How to determine the appropriate ventilation rate in the laboratory

10) Fire protection problems on fume hood pipes

11) Use safety fume hood

12) How to use laboratory fume hood effectively

13) Guide to regulations and standards for fume hoods

14) The true definition of high-performance fume hood

Form

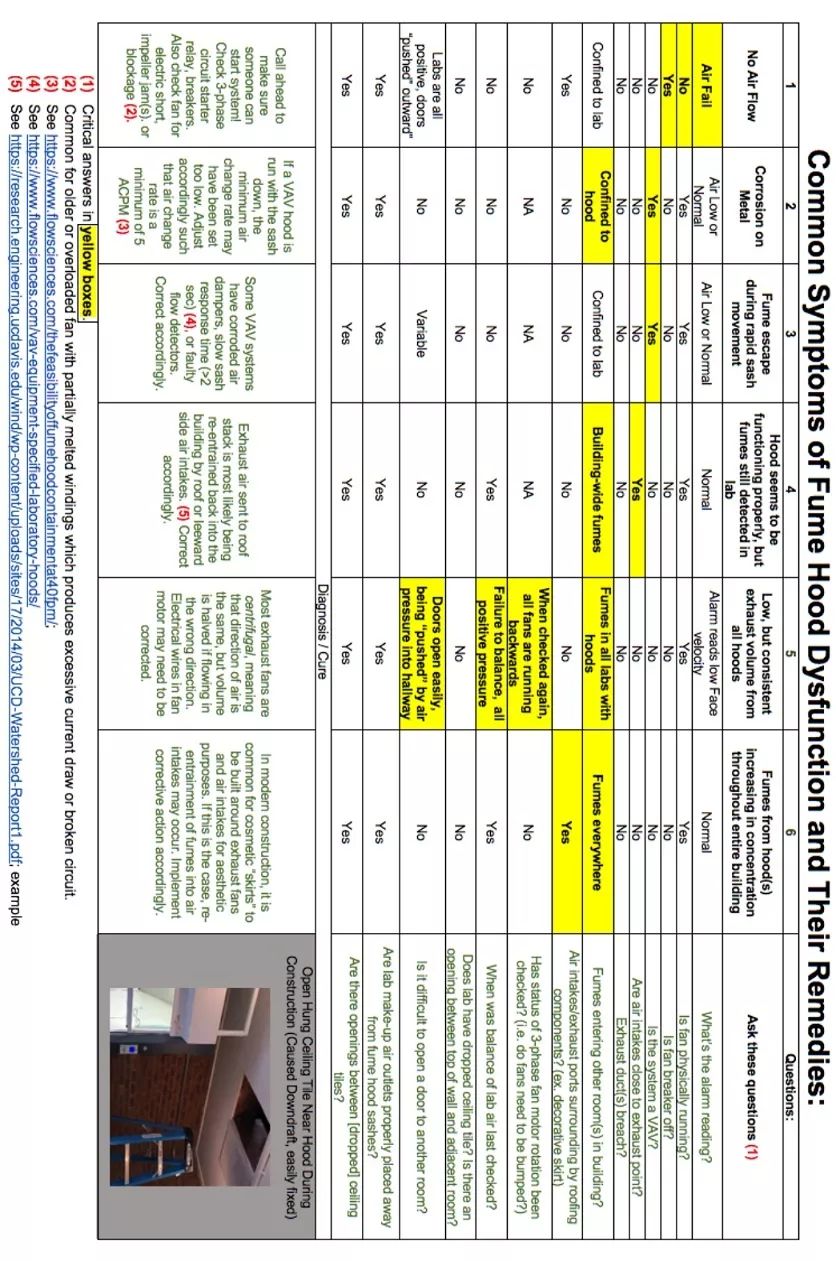

The following summary chart shows six main control problems, which may represent 8 in the 8/2 principle of fume hood. When things don't go as planned, fourteen questions and six diagnoses are helpful for architects and project managers to determine good design techniques and "tell" common problems.

The author invites you to make any comments on this article and the chart. As additional experience, these comments will make the summary of experience more comprehensive!