How to Determine the Appropriate Ventilation Rate of the Laboratory?

Date: 2022-01-19 Source: RUANQI Classification: Resources

Engineers must know the required ventilation rate per hour, depending on the type of building. Whether in educational institutions or hospital design laboratories, knowing the ventilation rate is the key.

A few years ago, I attended a week-long laboratory seminar at Harvard University. When we approached the part of the seminar concerning ventilation rate, I sat in my seat with great expectation. I finally got the final answer to the debate about hourly air change (ACH). I believe it was a gentleman from the Massachusetts Institute of Technology (MIT) who stood on the platform and asked the seminar participants about the correct value of ACH when designing the laboratory. After several answers ranging from 4 to 18 ACH, Mr. MIT thanked everyone for their answers and told them that they were all wrong. I sat on the edge of my seat, waiting to hear the correct answer. He went on to say that the correct answer is, I quote him, "It depends." I fell off the chair.

I didn't realize this at that time, but what that gentleman said was correct. After several years of designing laboratories including education laboratories, hospital laboratories, research and development (R&D) laboratories and pharmaceutical companies, the ventilation rate depends on the use of specific project types, the implementation of facility standards and regulations.

Relevant codes and standards

•2014 FGI Guidelines for the Design and Construction of Hospitals and Outpatient Facilities(inculde ANSI / ASHRAE / ASHE170)

•NFPAStandard45

•ANSI Z9.5

•OSHA

•ASHRAEStandard90.1

•California Mechanical Code(This is an example of a local regulation).

The following is a summary of the ventilation section of each regulation/standard, which can be used as a quick reference tool when discussing laboratory ventilation with customers.

Guidelines for the design and construction of FGI hospitals and outpatient facilities in 2014 (including ANSI/ASHRAE/ASHE standard 170)

ACH range: 4 to 10(USP 797 requires 30)

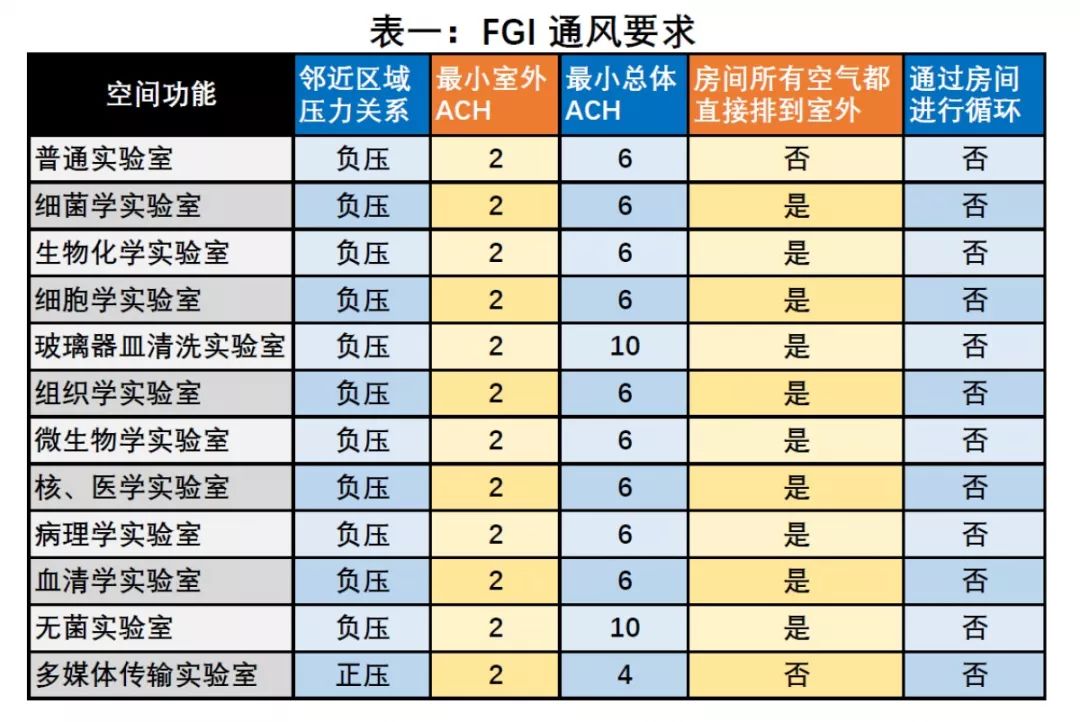

Combining this standard with ANSI/ASHRAE/ASHE standard 170, a comprehensive ventilation platform was developed. See the data in Table 7.1 for laboratory ACH rate. Table 1 shows the summary of the ventilation part of the table.

FGI guidelines also involve pharmaceutical companies, which can have 30 ACH to maintain proper cleanliness of the process. This standard requires pharmaceutical companies to design in accordance with USP 797 standard.

NFPA 45: Laboratory fire protection standard

ACH range: no range is given

This standard provides a general statement, that is, "the design of the laboratory ventilation system should ensure that the fire hazard and risk are minimized". This means that you need to consult the chemical consultant in the project to know the correct storage and dilution rate. Spaces and fume hoods containing chemicals should be continuously ventilated under normal operating conditions. While achieving this goal, the exhaust and water supply system must also be designed to prevent the door from opening due to pressure difference in case of system failure or fire or emergency. The ventilation system of the laboratory is designed to ensure that chemical smoke, steam or gas from the laboratory will not be recycled.

The design should ensure that the air pressure in the working area of the laboratory is negative relative to the corridors and non-laboratory areas of the laboratory space, except the positive pressure clean room. Opening doors, changing the position of sliding doors of fume hoods, and other short-term temporary activities will affect static pressure. Another exception is in the designated electrical classified hazardous area with positive pressure system, as described in NFPA 496: cleaned and pressurized enclosures for electrical equipment.

Special local exhaust ventilation system, such as snorkel, should have enough catching speed to carry released chemicals. It is important not to underestimate the factors needed to provide the appropriate capture speed. These calculations are in ACGIH Industrial Ventilation Guide, and can be carried out in the range of 75 to 2000 feet/minute according to the configuration and process.

ANSI Z9.5

ACH scope: "Air change per hour is not the basic concept of designing pollutant control system." However, it is recommended that the number of air changes for fugitive emissions and odors be 4-10 times.

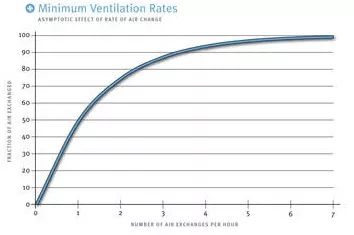

This standard is the most comprehensive and should be followed in any laboratory design. ACH efficiency is not specified in this standard. It only states that the specific room ventilation rate should be determined or agreed by the owner or his designee. All pollutants should be controlled at the source. The following parts of the standard are completely consistent with the MIT professor I mentioned earlier. It points out that it is impossible to determine the air exchange rate that meets all conditions: "The air exchange rate per hour is not the basic concept of designing pollutant control system." In fact, it further accurately states: "Too much airflow will lead to very low energy efficiency design."

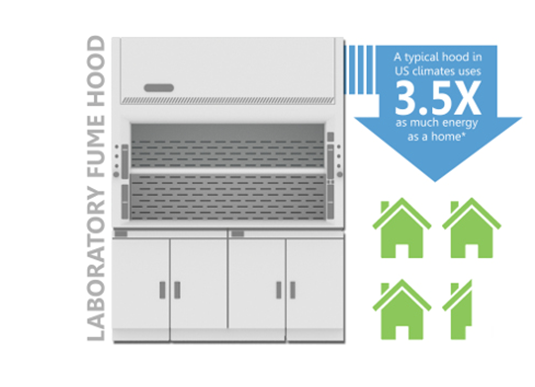

However, the standard does require dilution ventilation to control the accumulation of fugitive emissions and odors in the laboratory. However, catching smoke in fume hood is the main method of source exhaust ventilation. According to the heating, cooling and comfort requirements and the number and size of exposure control equipment, the typical dilution ventilation rate can be in the range of 4 to 10 ACH. This standard suggests to consider using VAV fume hood to save ventilation energy. This is a good place to save energy, because the air from the fume hood needs to be replaced by conditioned air. The conditioned air needs larger air handling units, coolers and boilers. The data released by the Department of Energy (DOE) shows that a single fume hood uses as much energy as 3.5 households, which really helps to reduce any ventilation related to the fume hood.

However, if VAV fume hoods are used, it is recommended that they be equipped with emergency control devices, so that even when the sliding door is closed, if overflow occurs, full-flow exhaust can be realized. When designing the ventilation system, we must consider the safety and energy use and the surface wind speed of the fume hood. The fume hood manufacturer must prove that the fume hood has passed the ANSI/ASHRAE standard 110 test: the test of the performance method of laboratory fume hood with selected face wind speed.

The typical range of surface wind speed is 0.4 m/s to 0.4 m/s. It is never recommended to operate below 0.3 m/s.

The surface speed of low-flow "energy-saving fume hoods" is 0.3 to 0.4 m/s, but these types of fume hoods must have excellent sealing characteristics and operate under the conditions of open windows, doorways and people traffic flow, because these will have adverse effects. Containment of chemicals in fume hood.

The airflow with a certain surface wind speed must be able to keep the steam concentration between 10% and 25% of the lower flammability limit (LFL) or the lower explosion limit (LEL). This is usually calculated by the chemical consultant. The air pressure in the laboratory is usually negative unless an attempt is made to protect the space, such as a clean room, in which case the space pressure will be positive. It is very important to design building envelope to reduce the amount of transferred air needed to maintain correct pressurization. The standard also recognizes that it is impractical to maintain the differential pressure on the open door due to the effective large leakage area. Door switches with alarm delay are usually used to avoid false alarms related to door openings.

The way to save energy and capital cost is not to fix the size of ventilation system to adapt to the total flow of fume hood. Diversity factors can be used to predict the actual number of fume hoods used at one time. When applying diversity factors, designers must consider a wide range of topics, including but not limited to: expansion considerations, the minimum and maximum ventilation rate of each laboratory, the number of fume hoods and researchers, sliding door management (users' sliding door habits), and the mode of using variable air volume fume hoods.

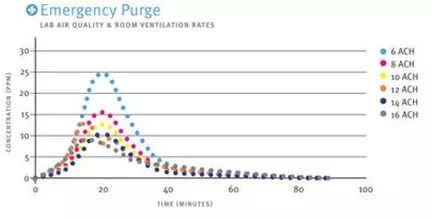

It is important for users to agree with diversity factors and understand the limitations of laboratories. If diversity factors are used, not all fume hoods can be used simultaneously. Air flow alarm system must be installed to warn users when the system runs beyond the capacity allowed by diversity. This standard also requires the design of emergency ventilation system when there is a certain type and quantity of chemicals or compressed gas in the laboratory to ensure emergency ventilation. This will be determined by the chemical consultant in the team, and will allow to increase the ventilation rate ACH in the space during the leak.

In the case of emergency mode or fire mode, if the room pressurization is not considered, the typical scheme of simply turning off the space supply and maintaining the exhaust flow cannot be carried out. The ventilation system shall not produce a large pressure difference, which will prevent the user from opening the door and leaving the area. Generally speaking, the standard stipulates that return air should not be used in laboratories with hazardous chemicals or biological hazards. As an energy-saving strategy, the energy recovery system should be evaluated to reduce the energy needed to adjust a large amount of external air intake.

Finally, the ventilation rate selected for the laboratory depends on the maximum thermal comfort airflow, dilution and replacement of pollutants not captured by the pollutant control device, and supplementary air to explain the operation of the pollutant control device, such as laboratory fume hood, space pressurization, or minimum occupancy ventilation. These factors must be considered before determining the ventilation rate.

OSHA

ACH range: No range is given.

OSHA requires that the ventilation hood surface wind speed always keep the inward air flow. The average surface wind speed is at least 0.5 m/s, and at least 0.35 m/s at any point. If there is an automatic control system and the fume hood complies with ASHRAE Standard110 under these conditions, it is allowed to reduce the wind speed by 0.3 m/s non-usability. The standard also requires sufficient surface wind speed, which is higher than 20% exceeding the lower explosion limit.

ASHRAE Standard90.1

ACH scope: No scope is given.

ASHRAE Standard90.1 allows the laboratory to avoid typical energy requirements in terms of energy recovery effectiveness and temperature reset strategy. According to this standard, buildings with laboratory ventilation exhaust flow higher than 5,000 cfm should have VAV exhaust ventilation system and/or provide energy recovery.

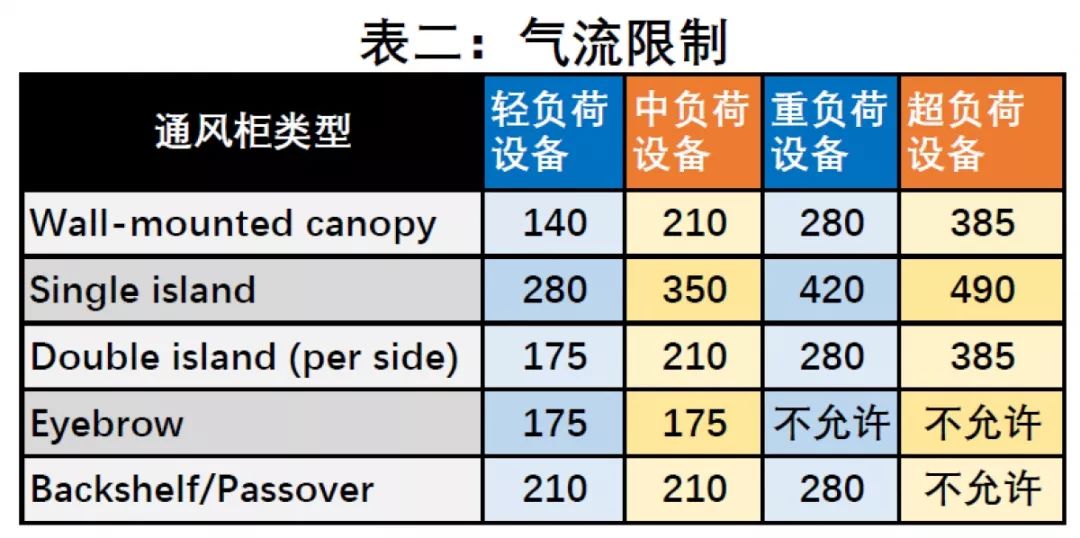

The system serving the laboratory space should reduce the exhaust and fresh air volume during the unoccupied period to the largest one of the three options: 50% of the regional peak air flow, the minimum outdoor air flow or the air flow rate standard required by applicable codes or certifications. The standard also specifies the allowable ventilation airflow through the trap hood (see Table 2).

California Mechanical Code

ACH range: 4 to 10

For educational laboratories, California regulations require 10 cubic feet per person (density of 25 people per 1,000 square feet) and 0.18 cubic feet per square foot. The implementation of the state's hospital regulations, the State Health Planning and Development Office (OSHPD), requires the specific ACH efficiency listed in Table 3.

Who's involved?

Knowledge of standards and specifications is not enough to design ventilation systems for laboratories. When working out ventilation strategies with users, it is very important to meet with the following stakeholders and design team members: end-user environmental health and safety (EH&S) department equipment engineer design team chemical consultant laboratory planner architect.

The ventilation rate selected for the laboratory depends on the maximum airflow of thermal comfort, dilution and replacement of pollutants not captured by the pollutant control device, and supplementary air for explaining the operation of the pollutant control device. Each factor will bring a puzzle. The end user will discuss how to use the system, which will affect the control strategy and how the laboratory planners choose the equipment. EHS will convey the standards set by the owner/company. Facilities engineers can have a deep understanding of building maintenance and energy usage. The chemical consultant will provide the data that affect the emergency exhaust requirements and the wind speed on the hood to maintain LEL. The laboratory planner will give advice on the amount of miscellaneous heat load and pollution source emissions. Finally, the architect will assist in providing information that is helpful to determine the ventilation seal used to maintain the pressure difference.

The strategies in the above specifications and standards will change according to the type of laboratory designed. The following are the considerations for different types of laboratories:

Facilities: Medical and health care standards and norms are not applicable. It is very important to determine the chemicals to be used and whether the emergency cleaning required by ANSI Z9.5 is needed. Unfortunately, due to the use of fume hoods in teaching laboratories, the diversity factors discussed above may be very small or even non-existent. Due to the course arrangement, these types of facilities can use VAV fume hood and vacant design.

Hospital: National laws and regulations, such as OSHPD, are the main driving factors of hospital ventilation rate. However, they should be regarded as the minimum requirements, and the final efficiency will be determined by knowing the usage and chemicals in the laboratory. If hospitals are stricter than California regulations, hospitals usually have their own guidelines and standards. It is also important to note that some standards contradict each other. If the facility uses both standards to design the project, it should be reviewed. One example is "laboratory, biochemistry" ventilation. FGI requires the room to be negative, and the air is directly discharged to the outside, while the state law requires the biochemistry to be positive, and it is not necessary to discharge the room air directly to the outside. If a pharmaceutical company is designed, USP 797 should be followed.

Research and Development (R&D): Medical standards and norms are not applicable. When deciding the ventilation of R&D facilities, it is helpful to know the purpose and plan of future growth. As mentioned earlier, the fume hood needs a lot of energy. If you don't fully understand how each department works, each department needs several ventilation cabinets. For example, I once participated in a project in which the company started to use 14 100% exhausted BSC. After spending some time talking with various departments, it is determined that only one BSC needs to be used up 100%. This not only saves the upfront cost of the exhaust fan and stainless steel piping system for the owner, but also saves the cost of large-scale air supply system, boiler and cooler, and introduces conditioned outside air to make up for the air exhausted through BSC.

When designing the laboratory, there is no single answer to the ACH rate. Designers need to ensure that they follow standard care. In order to provide real consulting services, the team must provide suggestions on safety, energy use, initial cost and suggested options to meet the specific needs of the facilities.