Standard Performance Test Laboratory of Fume Hood

Date: 2022-01-19 Source: RUANQI Classification: Resources

The performance test of fume hood is getting more and more attention. The performance test of fume hood is a rigorous and demanding process. At present, the performance test of fume hood in China has not formed a standardized market, and the entry threshold is low, which brings some troubles to the industry and users.

ICT2 WeChat official account will launch a series of articles to introduce various aspects of fume hood performance test, so as to clarify what fume hood performance test is and how to control the quality of laboratory ventilation engineering for concerned readers, laboratory users and laboratory builders. These series of articles will include:

1. Standard performance testing laboratory of fume hood;

2. Standard test method of fume hood performance (ASHRAE 110-2016 AM-AI-AU and EN 14175-3/4);

3. fume hood performance testing instruments and equipment;

4. Operation principle of fume hood;

5. Common problems in operation of fume hood/exhaust system;

6. How to use the fume hood correctly;

7. Acceptance standard of laboratory ventilation and fume hood (recommended).

Content navigation of this article

1. Introduction

2. Why do you need a fume hood standard performance testing laboratory?

3. ASHRAE 110-2016 Standard Performance Test Laboratory Requirements for Fume Hood

4. EN 14175 requirements for standard performance test laboratory of fume hood

5. ASHRAE 110-2016 and EN 14175-3:2019 are compatible with the requirements of performance testing laboratories.

6. How to judge whether the third-party fume hood testing laboratory meets the standard?

A. Have a testing laboratory that meets the standard requirements.

B. Have testing tools that meet the standards.

C. Have third-party testing qualification (CMA and CNAS)

a) How to query CMA qualification confirmation

b) How to query CNAS qualification

Introduction

Fume hood is one of the most important control equipment for laboratory pollutants, which plays an important role in the control of laboratory air quality. Fume hood manufacturers must prove the effectiveness of their products through successful pollutant control tests. Evaluating the performance of fume hood is an important link in laboratory pollutant control. The demand for efficient pollutant control equipment (usually fume hood) is truly international. Most laboratory staff want to have a safe working environment.

The fume hood standard performance testing laboratory is essential for fume hood research and development and third-party testing, and it also makes it possible to compare the performance data of fume hoods produced by different countries and manufacturers.

The performance test (type test or AM test) of fume hood has strict environmental and test hardware requirements. In this paper, the requirements of ASHRAE 110-2016 and EN 14175-3:2019 for test environment will be introduced in detail, and some matters needing attention in the establishment of fume hood standard test laboratory will be given, which will provide reference for fume hood manufacturers or third-party companies interested in building standard test laboratories, and also provide the basis for customers to choose third-party fume hood performance test companies.

It must be emphasized that the test data of any test laboratory that does not meet the standard requirements will be invalid.

Why do you need a fume hood standard performance testing laboratory?

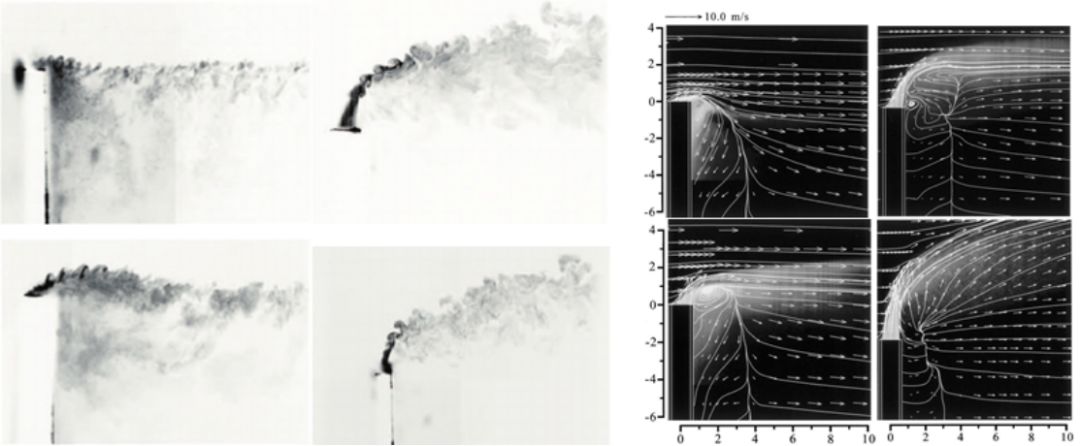

The standard performance test laboratory of fume hood should start with ASHRAE 110-AM/EN 14175-3 test. The purpose of AM test/type test is to test the design of fume hood under perfect conditions. The fume hood is a product of aerodynamics and fluid mechanics, and any condition that affects the fluid behavior will affect the performance of the fume hood. In order to avoid external factors affecting the performance of fume hood, it is necessary to have a standard test environment.

Another important reason is that there are many manufacturers all over the world. In order to produce comparable fume hoods, the test conditions should be the same. It is possible for the standard testing laboratory to compare the performance parameters of fume hoods produced by different countries and manufacturers.

ASHRAE 110-2016 Requirements for Standard Performance Testing Laboratory of Fume Hood

ASHRAE, American Association of HVAC Engineers, is "a global association dedicated to promoting human welfare through sustainable technologies in the built environment." Including building systems, energy efficiency, indoor air quality and sustainability, HVAC systems from residential and personal vehicles to commercial aircraft, and of course all systems in scientific laboratories. Its history can be traced back to 1894, making it one of the primary sources of industry standards, operation practices, research and other fields.

ASHRAE Standard 110, or ASHRAE 110 for short, explains a method to test the performance of laboratory fume hood. Basically, it outlines the quantitative test methods used to determine the pollutant control ability of fume hood, such as capturing and discharging exhaust gas. ASHRAE 110 is the most widely used test standard of fume hood in the world.

▲ The latest version of ASHRAE 110 is the 2016 version

ASHRAE 110-2016 gives detailed requirements for the standard conditions to be met by the fume hood performance test laboratory (AM test laboratory) in Chapter 5, Test Conditions:

5. TEST CONDITIONS

5.1 Room Ventilation

5.1.1 Field Test Requirements. Room ventilating systems, both supply and exhaust, including the fume-hood exhaust, shall be in full normal operation.

5.1.1.1 Airflow systems in the laboratory shall be properly commissioned prior to beginning the test. This includes calibration of airflow controls; calibration of automatic temperature controls; balance of supply air; completion of a duct traverse on the exhaust duct and, if used, on the auxiliary air duct; and completion of an air balance of the total exhaust flow. If the laboratory has standard procedures limiting the number of hoods in use at any one time, the conditions of use corresponding to the standard procedures shall be established.

5.1.1.2 The temperature of the room shall be typical for laboratory use, nominally 72°F±5°F (22°C±2.7°C).

5.1.2 Manufacturer’s Test Laboratory (AM Testing).

The following additional requirements shall apply when testing in a manufacturer’s test laboratory.

5.1.2.1 The manufacturer’s test laboratory shall not have excessive drafts or crosscurrents. Measured crosscurrents in an area 1.5 ft (0.5 m) from the face of the hood shall be no greater than 30 fpm (0.15 m/s).

5.1.2.2 The manufacturer’s test laboratory shall have room pressurization control capable of measuring and maintaining a pressure differential of 0.02 in. of water (5 Pa) below the static pressure outside the test room.

5.1.2.3 The manufacturer’s test laboratory shall have the hood volumetric flow measured in accordance with ASHRAE Standard 41.2, Standard Methods for Laboratory Airflow Measurement.3

5.1.2.4 The manufacturer’s test laboratory shall have the hood static pressure measured at the exit plane at the top plane of the collar(s) in accordance with ASHRAE Standard 41.3, Standard Method for Pressure Measurement.4

5.1.3 Reporting. The report for an “as manufactured” (AM) test shall include a sketch of the test laboratory that documents the location of the test hood and any equipment that might affect hood performance. In particular, the sketch, or accompanying text, shall identify the location and type of supply fixtures, the supply air system, and the supply air controls (volumetric flow, temperature, pressure, etc.).

5.3 Background Level

5.3.1 Zero Background Test. Before beginning the testing and frequently during the testing period, verify that the instrument is adequately zeroed.

5.3.2 Background Tests. Occasionally during the hood testing, verify that the room background has remained below the detection limit. Background levels of contaminants can be observed if the ventilation system demonstrates reentry or if the laboratory releases compounds that are detected by the instrument.

5.3.3 Test Results. If air contaminants are sensed by the detector as tracer gas at more than 10% of the presumed control level, use of such materials shall cease until background readings fall below 10% of the presumed control level. Otherwise, substitution of another tracer gas meeting the requirements of Section 4.1.2 shall be implemented.

Organize relevant contents and translate them as follows:

1. the laboratory must be kept at 22 2.7℃;

2. Disturbance flow must be less than 0.15m/s at 0.5m from the opening surface of the fume hood;

3. The test laboratory room must maintain a static pressure difference of -5pa;

4. The test laboratory must measure the volume flow of the fume hood according to ASHRAE 41.2 "Standard method of laboratory gas flow";

5. The test laboratory must measure the static pressure at the top outlet of the hood of the fume hood according to ASHRAE 41.3 "Standard method for pressure measurement";

6. The concentration of tracer gas should be less than 10% of the control concentration;

The above is the stipulation of ASHRAE 110 on AM test conditions, which gives the condition parameters needed for the test. It serves as the basis for judging whether the hardware and control of a test laboratory meet the standards.

EN 14175 requirements for standard performance test laboratory of fume hood

EN 14175 is a pan-European test method for fume hood performance. EN 14175-3 and ASHARE 110 are both methods to measure the pollution control of fume hood, but they are quite different in equipment and calculation.

EN 14175 has seven parts:

EN 14175-1 terminology of fume hood

EN 14175-2 requirements for safety of fume hood

EN 14175-3 type test of fume hood

EN 14175-4 field test method

EN 14175-5 installation and maintenance

EN 14175-6 VAV performance test

EN 14175-7 fume hood for high heat and acid load We will only pay attention to EN 14175-3, which defines the pollution control and performance evaluation of fume hood.

▲ The latest version of EN 14175-3 is the 2019 version

With regard to the standard conditions that the fume hood performance test laboratory (type test of EN 14175-3) needs to meet, the detailed requirements of EN 14175-3 are given in Chapter 5, Test Room and General Test Conditions:

4 Test room and general test conditions

4.1 Dimensions and construction

The test room shall consist of an enclosure of cuboid shape, constructed of suitable materials, within a building or laboratory. The internal width and length shall be not less than 4,0 m and the ceiling height not less than 2, 7 m. The ceiling and floor shall be level and the room shall be devoid of internal supports, internal walls or other obstacles to the airflow.

4.2 Test room conditions

The room air temperature shall be (23 ± 3) °C. The make-up air temperature during measurements shall be room air temperature ±1 °C. Temperature gradients shall be avoided as far as possible. Th e make-up air shall be supplied at a distance greater than 2 m from the front of the fume cupboard.

The test zone boundary shall extend approximately 1,5 m in front of the fume cupboard and approximately 1,0 m from the outer sidewalls of the fume cupboard over the full room height.

Room extract air shall be extracted symmetrically on the opposite side to the make-up air supply and from outside the test zone. The air speed shall be less than 0,1 m/s at the test zone boundaries. Care shall be taken regarding uncontrolled air streams and draughts entering into the test room.

Any device the temperature of which exceeds 40 °C, except components which form part of the fume cupboard and/or the test equipment, shall be located outside the test zone boundaries.

The air extracted from the test room shall be discharged to atmosphere in such a way as to prevent its re-entrainment in the make-up air.

4.4 Test conditions

4.4.1 General

No person other than the operator(s) shall be present in the test room during the measurements. No person shall remain in the test zone during the measurements.

There shall be no unnecessary obstructions or equipment within the test zone. No equipment other than that necessary for the tests shall be in the fume cupboard.

Windows and doors of the test room shall remain closed during measurements.

NOTE Observance of all test conditions is crucial for reproducibility and repeatability of the test results. The related contents are sorted out and translated as follows:

1. The laboratory should be built in the room, and the cuboid shell should be made of suitable materials;

2, the internal width and length should be not less than 4 meters, the ceiling height should be not less than 2.7 meters;

3. The ceiling and floor should be horizontal, and there should be no internal support, internal walls and other obstacles hindering airflow in the room;

4. The indoor air temperature should be 23 3℃. The temperature of make-up air during measurement should be 1℃ of room temperature;

5. The fresh air supply position should be more than 2m away from the front of the fume hood;

6. The interference flow within the boundary of the test area must be less than 0.1m/s;

7. The air discharged from the test room should be prevented from entering the room again through fresh air;

8. There must be no unnecessary obstacles or equipment in the test area;

The above is the requirement of EN14175-3 for performance test of fume hood, which gives the conditions and parameters needed for the test. It serves as the basis for judging whether the hardware and control of a test laboratory meet the standards.

ASHRAE 110-2016 and EN 14175-3:2019 are compatible with the requirements of testing laboratories. (Take ICT2 fume hood standard performance testing laboratory as an example)

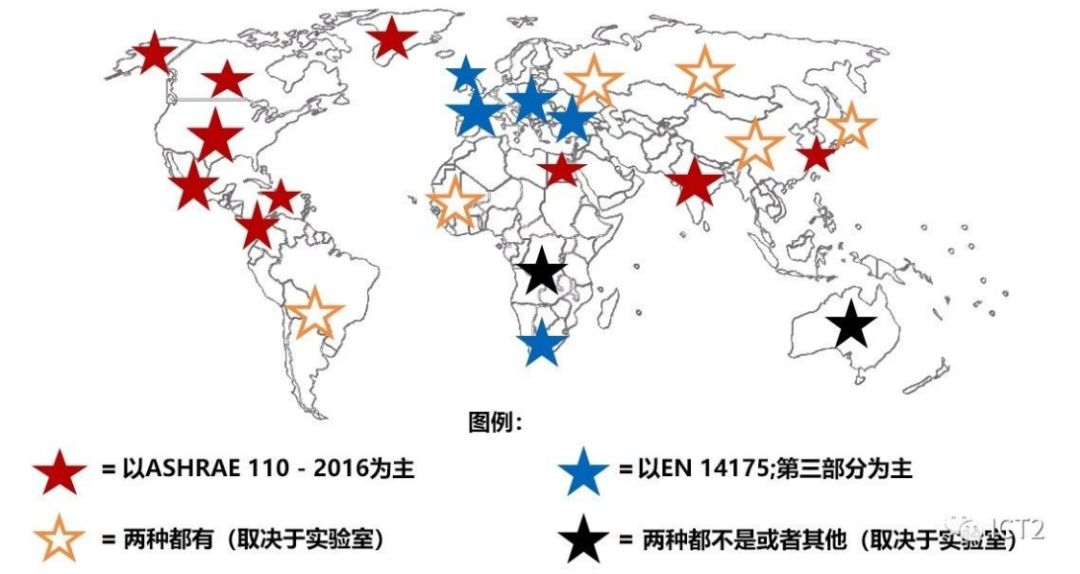

ASHRAE 110 and EN 14175 are two widely used test standards for fume hoods. The map of the world shown below describes the distribution of these two standard methods. Orange stars indicate countries that use these two standards. The above map clearly indicates the widely used test standards in each area. Wider areas (orange stars) use both standards.

In our country, both ASHRAE 110 and EN 14175 are adopted. Then it is necessary to establish a testing laboratory that is compatible with both methods.

From the above description, it can be seen that to establish a test laboratory compatible with ASHRAE 100 and EN 14175, the following requirements should be fully met:

1. the laboratory should be built in the room, and made of suitable materials cuboid shell;

2. the internal width and length should be not less than 4 meters, the ceiling height should be not less than 2.7 meters;

3. The ceiling and floor should be horizontal, and there should be no internal support, internal walls and other obstacles hindering airflow in the room;

4. The laboratory must be kept at 22 2.7℃; The temperature of make-up air during measurement should be 1℃ of room temperature;

5. The fresh air supply position should be more than 2m away from the front of the fume hood;

6. The interference flow within the boundary of the test area must be less than 0.1m/s;

7. The air discharged from the test room should be prevented from entering the room again through fresh air;

8. There must be no unnecessary obstacles or equipment in the test area;

9. A static pressure difference of -5pa must be maintained in the test laboratory room;

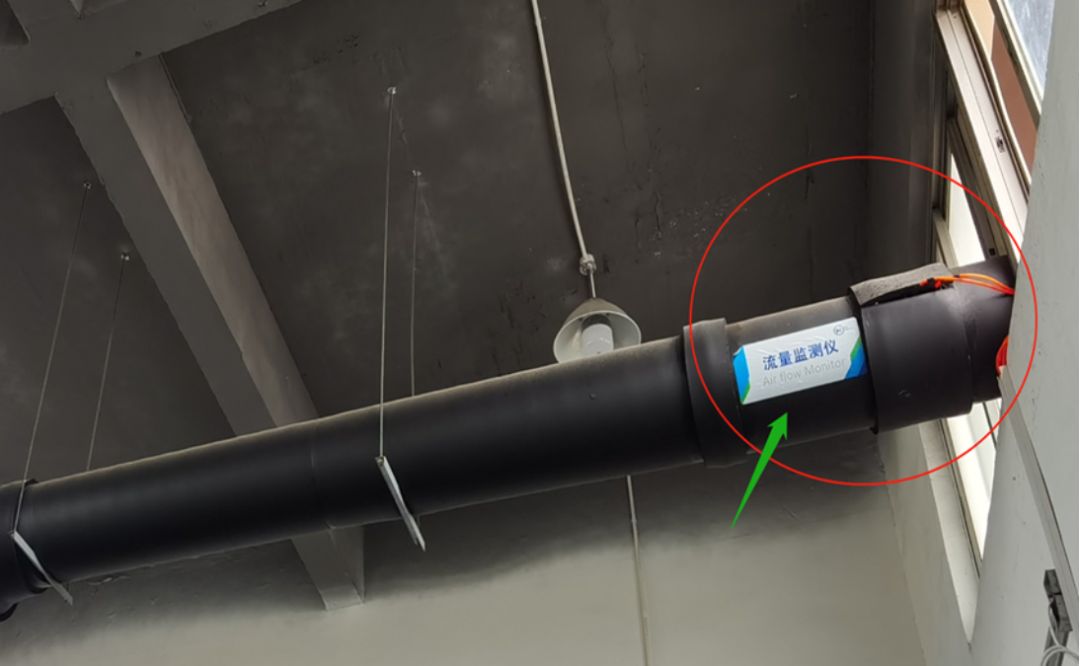

10. The test laboratory must measure the volume flow of the fume hood according to ASHRAE 41.2 "Standard method of laboratory gas flow";

11. The test laboratory must measure the static pressure at the top outlet of the hood of the fume hood according to ASHRAE 41.3 "Standard method for pressure measurement";

12. The concentration of tracer gas should be less than 10% of the control concentration;

Any of the above parameters looks simple. But it's not. Let's take a look at what a standard compatibility testing laboratory has done to meet the test conditions of these standards:

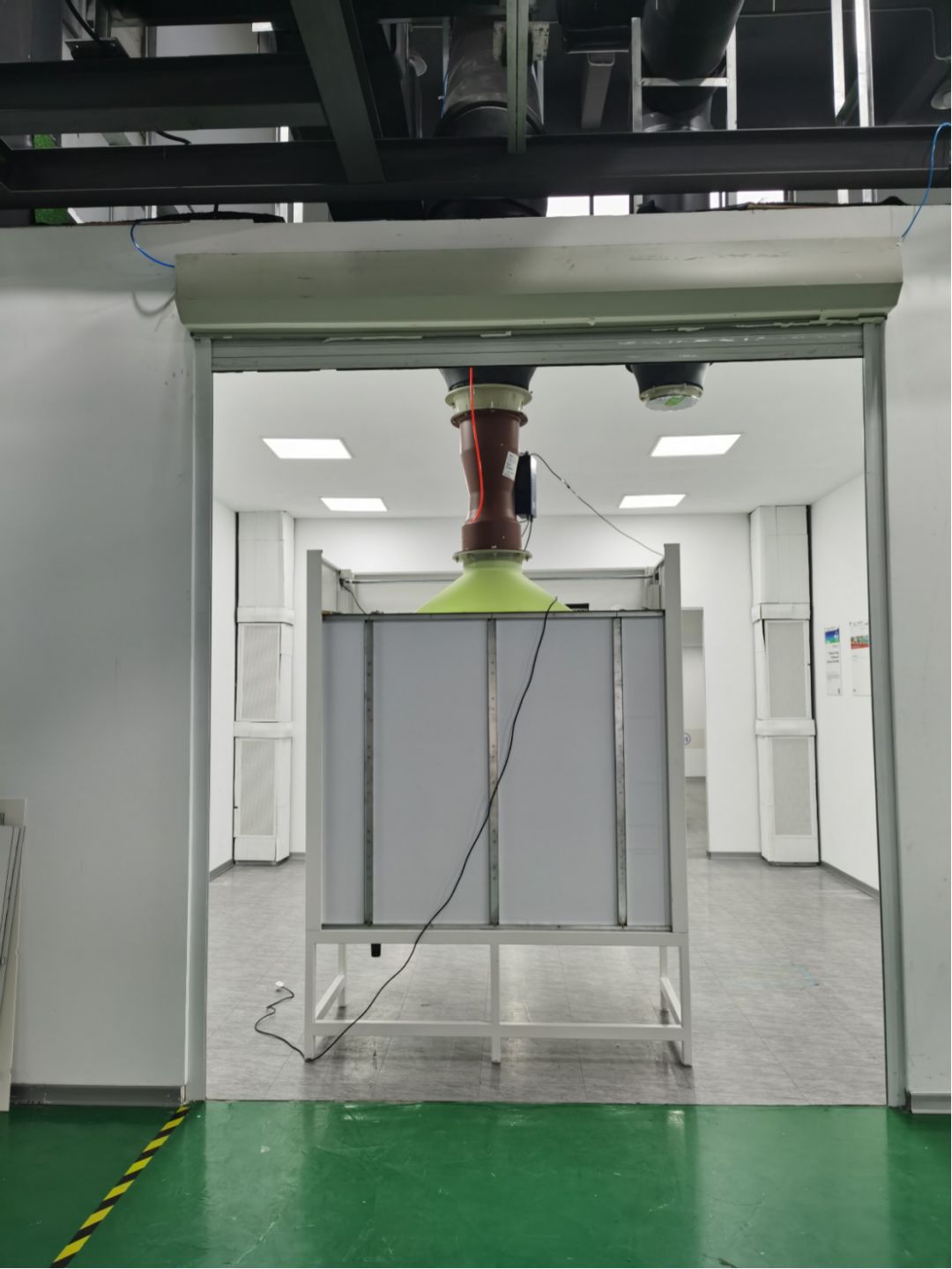

▲ Figure 1 Overall appearance, roof exhaust system and temperature control host

▲ Figure 2 Test laboratory roof, complex fresh air and exhaust system

▲ Figure 3 Test laboratory roof, complex piping system

▲ fig. 4 test the peripheral roof of laboratory room, fume hood exhaust system, room independent exhaust system and temperature control host.

The above is the general preview of ASHRAE 110-2016 and EN 14175-3:2019 compatible fume hood standard testing laboratory.

In order to maintain these parameters, a standard testing laboratory needs to be carefully designed, including fresh air system, exhaust system, HVAC and SF6 gas cylinder storage area, etc.

It is important to note that both ASHRAE 110 and EN 14175 need to use a large amount of SF6 as the tracer gas in the testing process. The fume hood requires 0.05 ppm to control SF6 leakage. One liter of SF6 is enough to pollute 20 million liters of air. A common fume hood (1.5 meters as reference), during the whole test process, ASHRAE 110 needs about 94 liters of SF6, and EN 14175 needs about 20.6 liters of SF6.

It is a difficult problem to control SF6 background pollution in testing laboratory. When designing the test laboratory, we must carefully consider the exhaust position of the fume hood and the local hydrological data.

▲ Local hydrological information to be considered in background SF6 control when designing fume hood exhaust.

How to judge whether the third-party fume hood testing laboratory meets the standard?

A third-party fume hood performance testing laboratory, which should meet at least the following three aspects:

A. Have a testing laboratory that meets the standard requirements (refer to the parameters listed in this article);

B. Have testing tools that meet the standards (* In the next article, ICT2 will focus on testing instruments and equipment of fume hood)

C. Have third-party testing qualification (* currently recognized CMA or CNAS in China)

A. Have a testing laboratory that meets the standard requirements

From the above description, it can be seen that the test laboratories of ASHRAE 100 and EN 14175 or the laboratories compatible with them should fully meet the requirements. Many important parameters are normalized.

There are two ways to judge whether the third-party testing laboratory meets the standard requirements:

First, ask the third-party test laboratory manager for some certification documents or test parameters that meet the standards;

Generally, the testing laboratory that meets the standard requirements is the basis for the third-party testing company to provide services. Logically, these requirements must be met before providing third-party testing services. Third-party companies often seek qualified companies or experts to certify testing laboratories to ensure that laboratories meet the requirements of standards.

Take ICT2 fume hood performance testing laboratory as an example: ICT2 invited Creative Solutions to certify its testing laboratory and obtained the certification that EN 14175 and ASHRAE 110 are compatible.

In addition, the third-party testing company has the responsibility and obligation to announce the basic information and parameters of the laboratory to the market or users, and provide relevant documents to prove that the laboratory meets the requirements of the standard. As customers, they also have the right to ask for some supporting documents or test parameters from third-party test laboratories.

Second, through field visits, confirm whether the laboratory parameters meet the standard requirements.

As a general user, you can start from the easiest place to judge. The following parameters can be obtained by simple observation or testing, and can be used as a method to quickly judge whether the standard requirements are met. For example:

1) According to EN 14175, the laboratory should be built in a room with a cuboid shell made of suitable materials;

2) The size of the test laboratory, EN 14175 gives the requirements that the internal width and length should be no less than 4 meters and the ceiling height should be no less than 2.7 meters;

3) For the temperature of the test laboratory, ASHRAE 110 requires that the laboratory must be kept at 22 2.7℃, and EN 14175 requires that the indoor air temperature should be 23 3℃;

4) With regard to relative pressure, during the whole test process of ASHRAE 110, the room must maintain a static pressure difference of -5pa, and EN 14175 should maintain a slight negative pressure during the whole process;

5) With regard to lateral interference flow, ASHRAE 110 requires that the interference flow must be less than 0.15m/s at a distance of 0.5m from the opening face of the fume hood; EN 14175 requires that the interference flow within the boundary of the test area must be less than 0.1m/s;

B. Have testing tools that meet the standards

The performance test of fume hood is a professional and complicated process. This process requires several professional testers and a series of testing instruments, equipment and software that meet the standard requirements. It is beyond the scope of this article to explain the test hardware of fume hood in detail, but it is worth emphasizing that if there is no test tool that meets the standard requirements, the tested fume hood data will be invalid. ICT2 will be introduced in detail in the next tweet about fume hood performance testing tools.

C. Have third-party testing qualification

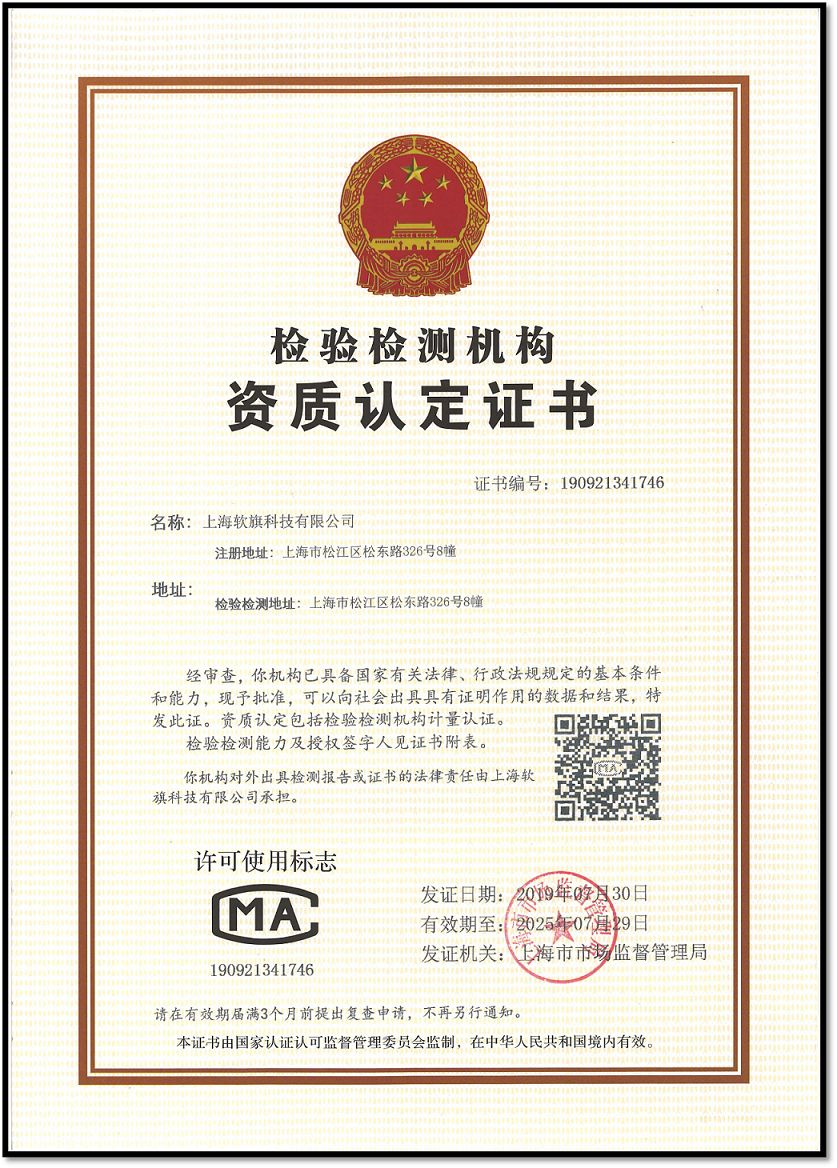

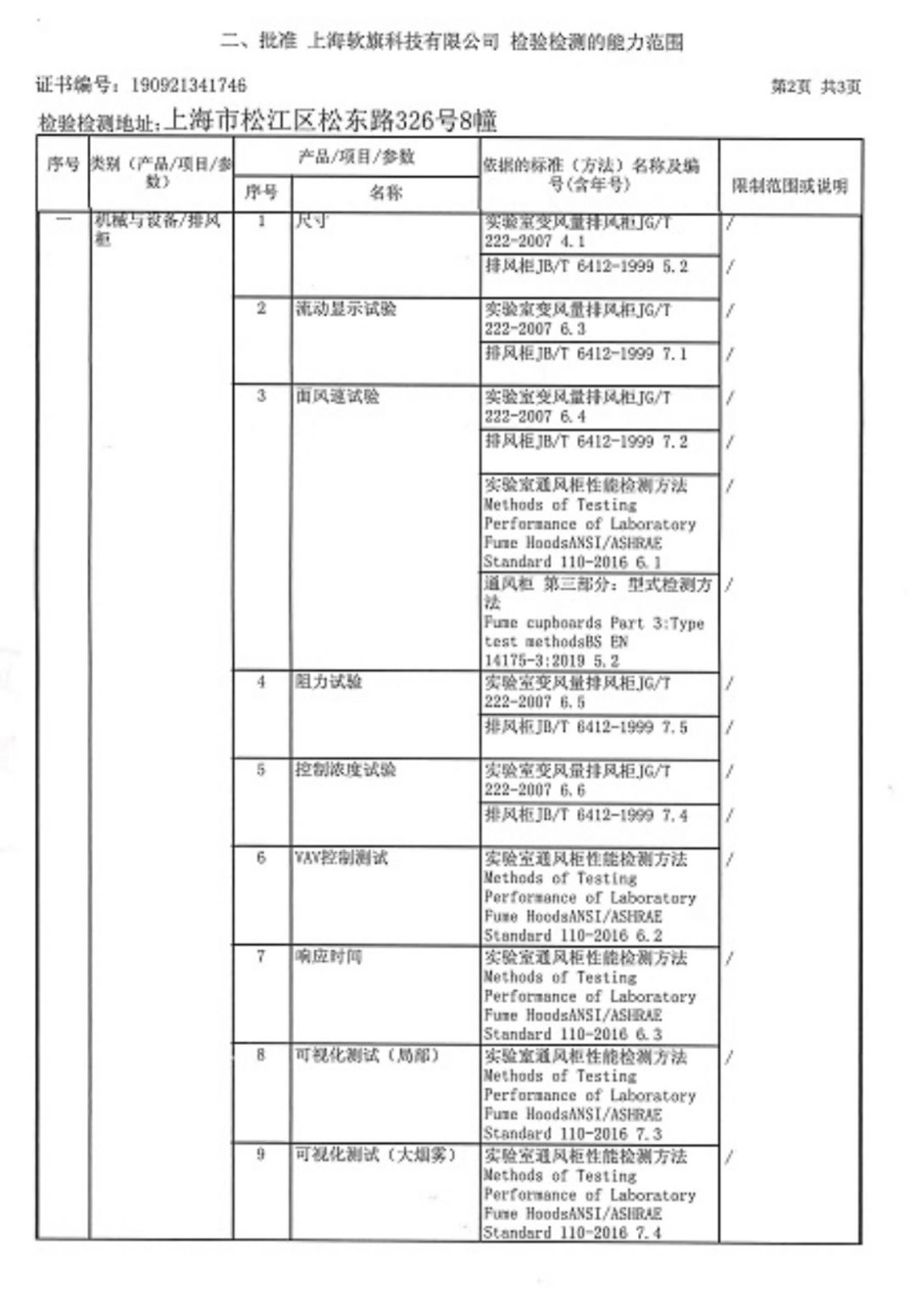

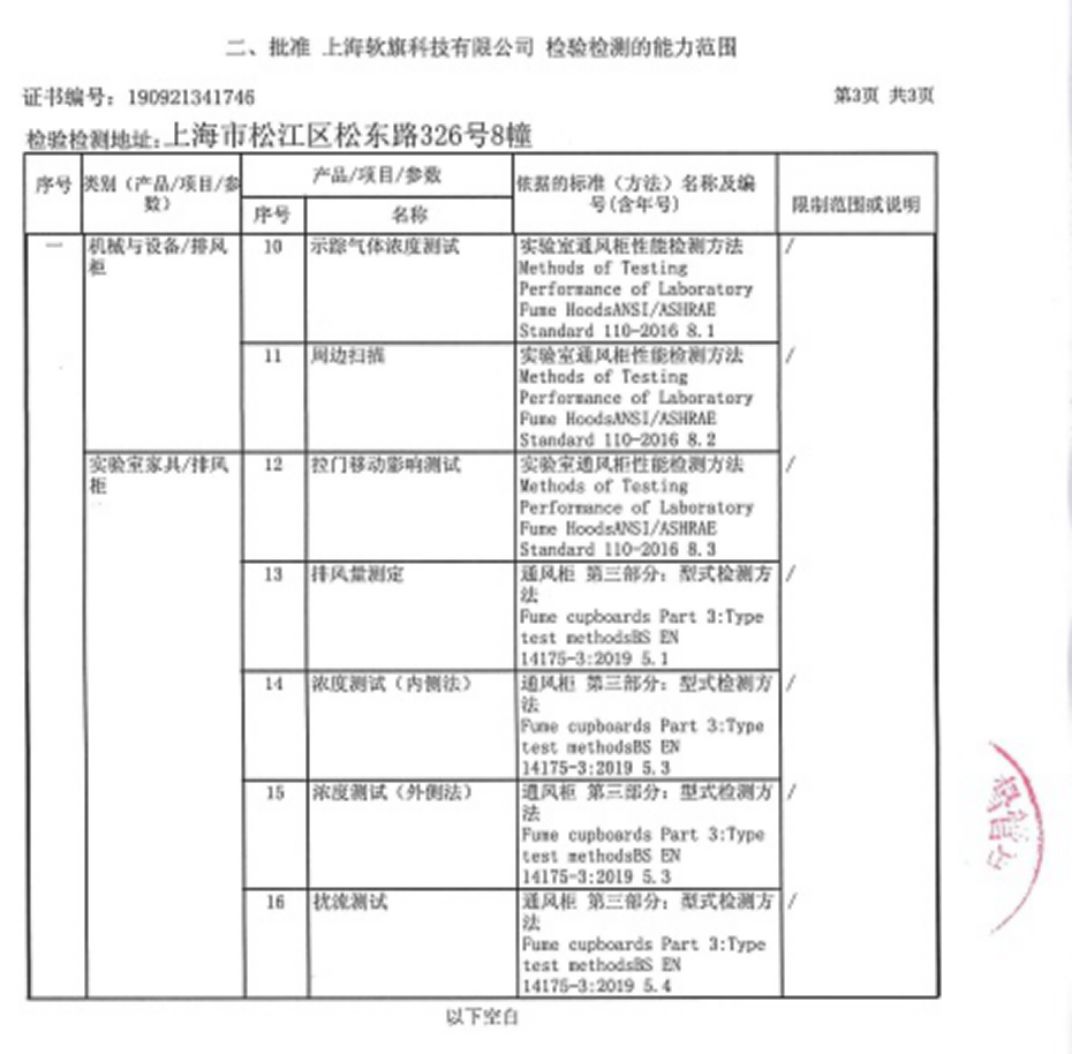

At present, CMA and CNAS certification systems are generally recognized in China. Generally, when a third-party testing company obtains CMA and CNAS certificates, the organization will issue a certificate of certification and an attachment of testing capability range. Users can confirm the testing qualifications and capabilities of third-party companies by asking for certification certificates from third-party testing organizations or inquiring online. Then, as ordinary users, how do we inquire about the qualifications and capabilities of a third-party testing company? Take the CMA/CNAS certification obtained by ICT2- Shanghai Soft Flag Technology Co., Ltd. as an example:

CMA qualification inquiry

CMA is the abbreviation of China inspection body and laboratory approval. A testing institution that has obtained the certificate of laboratory qualification (metrological certification) may use CMA mark on the testing (testing, testing) certificate and report according to the items listed in the certificate. For testing institutions, it is the mandatory approval system for testing institutions to enter the testing service market, that is, only those institutions with metrological certification qualification and legal status of metrological certification can provide testing services for the society.

Generally, when a third-party testing company obtains CMA certificate, the organization will issue a certificate and an attachment of testing capability range. Take the CMA certification obtained by ICT2- Shanghai Soft Flag Technology Co., Ltd. as an example:

▲CMA certificate of ICT2

◆

◆

▲ Attached table of CMA qualification certificate of ICT 2 testing laboratory, which contains testing items

Note: It is not enough for a third-party company to issue CMA certificate, but also to issue the approved testing items. Generally, if CMA certification mark is used in a test report, it means that the third-party company has the test qualification of the items included in this report. Otherwise, it will violate the relevant CMA regulations, and users can report to relevant departments.

CMA qualification can't be queried in official website, so generally, in order to confirm whether the third-party company has the corresponding CMA qualification, the third-party company can be required to present the original certificate of conformity issued by CMA and the schedule of testing items.

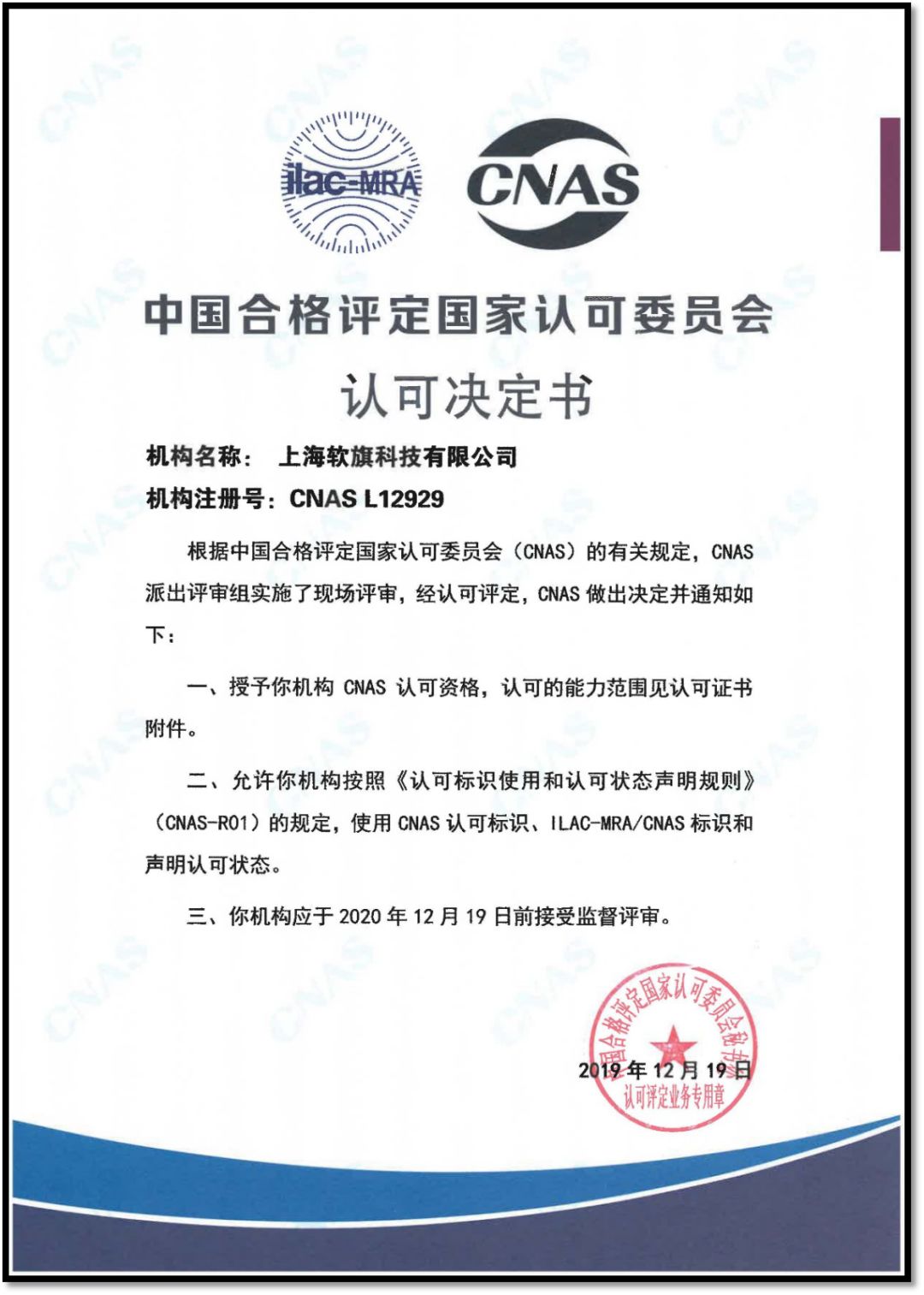

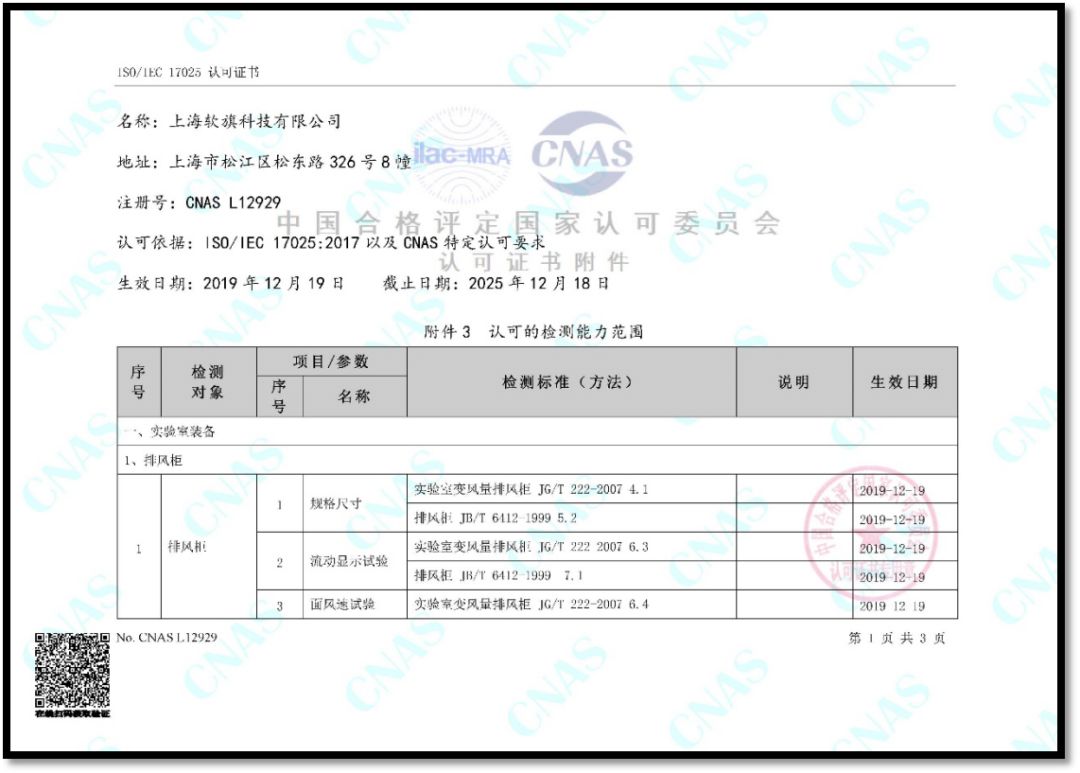

CNAS qualification inquiry

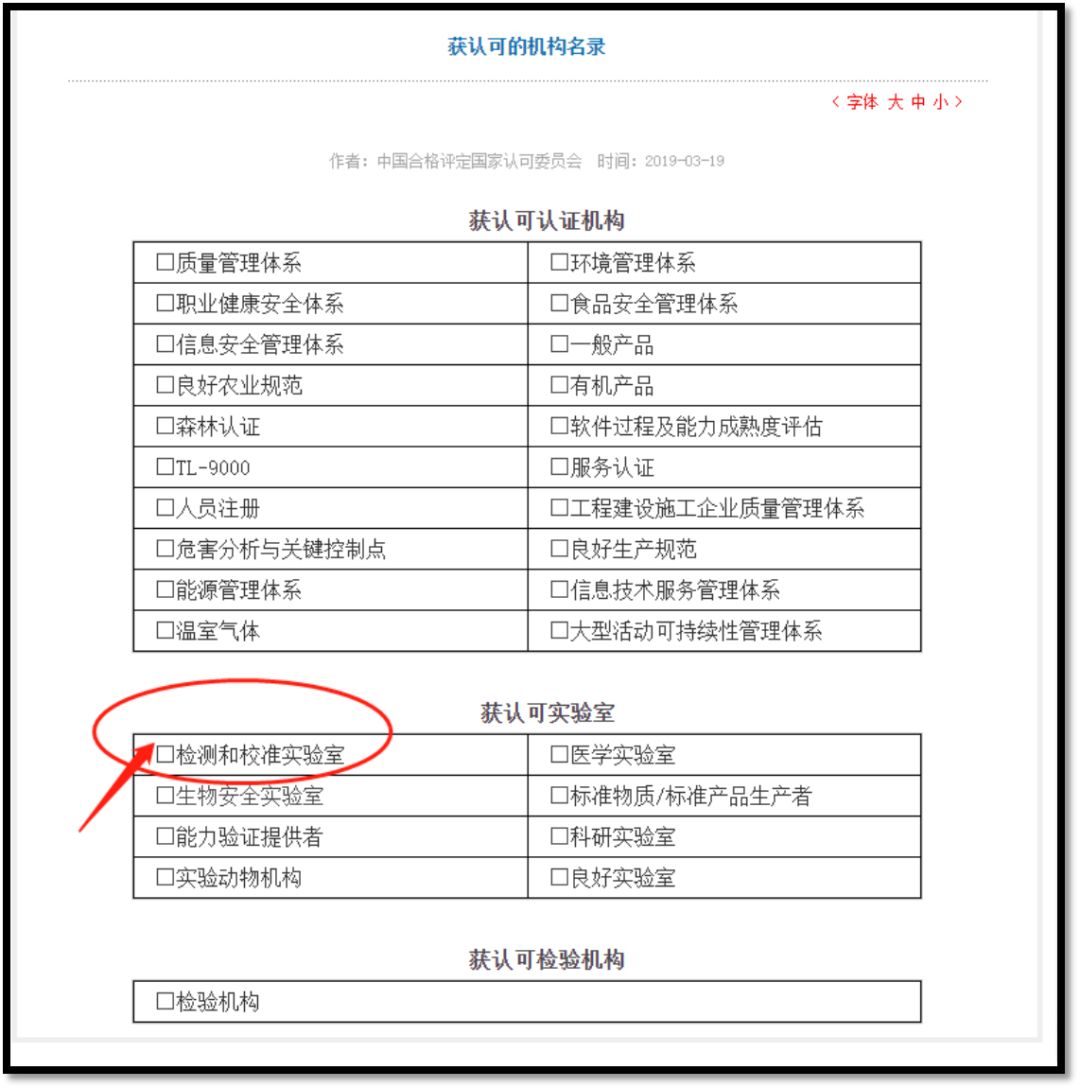

CNAS is the English abbreviation of accreditation service for conformity assessment (China National Accreditation Committee for Conformity Assessment). It is a national accreditation body approved and established by the National Certification and Accreditation Administration in accordance with the provisions of the Regulations of the People's Republic of China on Certification and Accreditation, and is responsible for the accreditation of certification bodies, laboratories, inspection bodies and other related institutions. CNAS evaluates and supervises the management and activities of conformity assessment organizations (such as certification organizations, laboratories and inspection organizations), confirms whether they have the ability to carry out corresponding conformity assessment activities (such as certification, testing, calibration and inspection, etc.), confirms the authority of their conformity assessment activities, and plays the role of recognition and restraint.

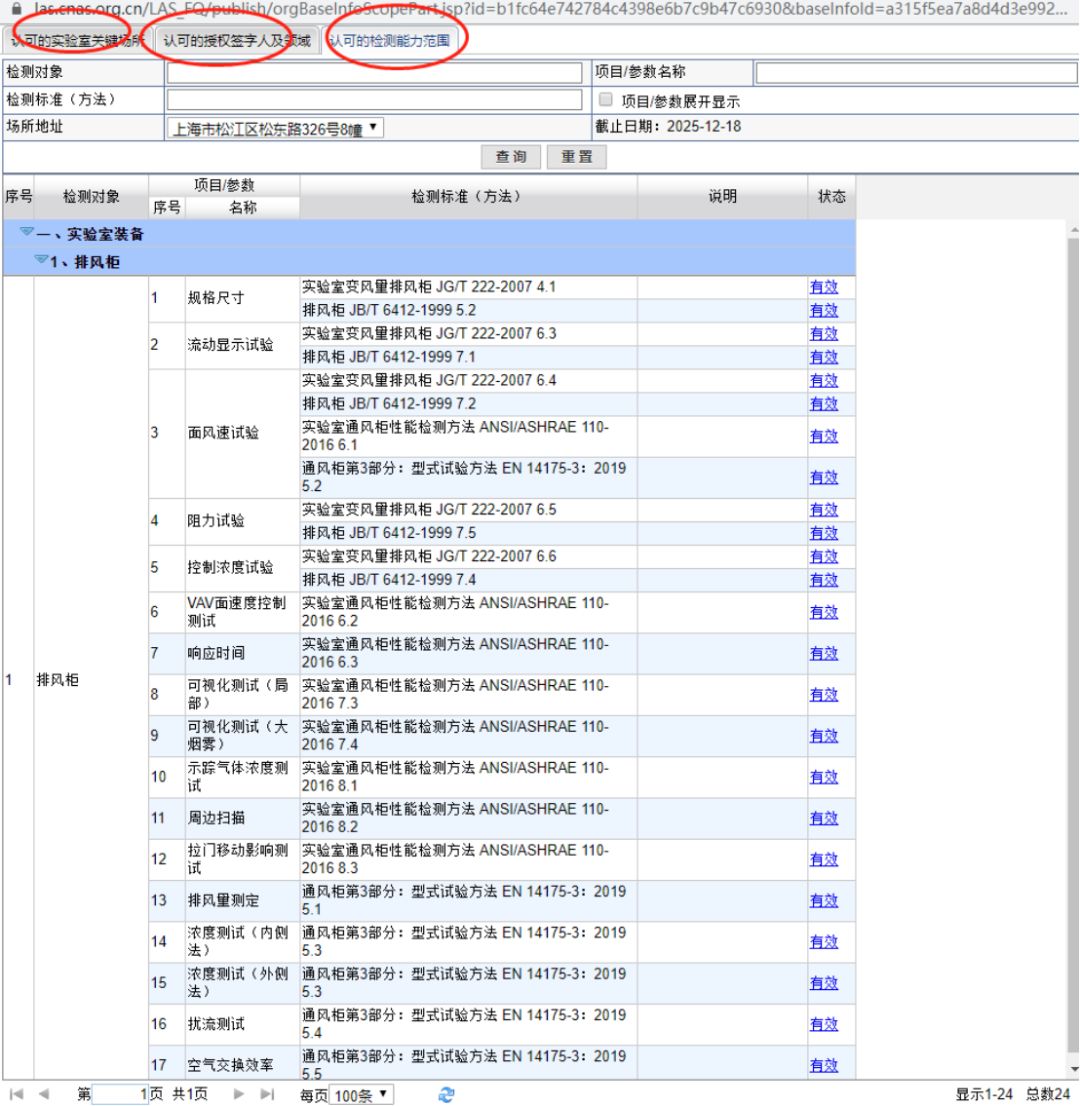

Generally, when a third-party testing company obtains CNAS management level or qualification certification, the organization will issue a certification certificate and attachment of testing capability range. Take the CNAS certification obtained by ICT2- Shanghai Soft Flag Technology Co., Ltd. as an example:

▲ Attachment of CNAS accredited testing capability range of ICT 2 testing laboratory

Note: It is not enough for a third-party company to only issue CNAS certification, but also to issue an attachment that recognizes the scope of testing capabilities. In addition, users can also inquire about the qualifications of third-party companies and the recognized testing capability range through CNAS official website.

How to inquire about the qualification and capability range of a third-party testing company? Or take ICT2- Shanghai Soft Flag Technology Co., Ltd. as an example:

1. Enter CNAS https://www.cnas.org.cn/, official website

2. Click on the yellow arrow to enter the "list of accredited institutions" and select the scope of the third-party testing company to be inquired. *ICT2 fume hood performance test belongs to "Testing and Calibration Laboratory"

◆

The above is a simple query method of whether a third-party company has CNAS qualification and capability range.

Concluding Remarks

The above is the requirement of ASHRAE 110 and EN 14175-3 fume hood standard performance testing laboratory. I hope this article can give some reference to peers. At the same time, interested customers are also welcome to visit and guide the ICT2 fume hood performance test laboratory.