False Statement About Surface Wind Speed

Date: 2022-01-19 Source: RUANQI Classification: Resources

There are some wrong or false statements about the surface wind speed. Some of these false or false statements have even become industry consensus.

What is the surface wind speed?

No matter ASHRAE 110, EN 14175 or JB/T 6412-1999, the surface wind speed is defined as the average air speed perpendicular to the section of the sliding door of the exhaust hood, which is usually expressed in meters per second (m/s) or feet per minute (FPM).

*100 FPM = 0.51 m/s

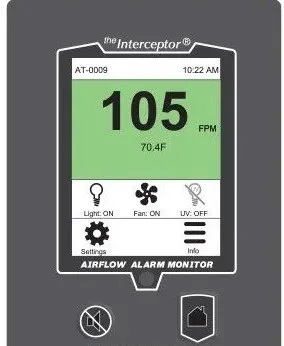

For users, they may only pay attention to the readings of the surface wind speed monitor, as shown in the figure below. This kind of monitor is only a simple measurement of the air velocity entering the fume hood, rather than the standard definition of surface wind velocity.

There is no relationship between surface wind speed and pollutant control! When you look at the monitor/alarm of the fume hood, the surface wind speed reading is between 0.4 m/s and 0.6 m/s. What is this actually telling you? Many people think that this figure of wind speed indicates that the exhaust hood is running safely. This is not correct. It is wrong to use only the surface wind speed as the safety measure of the fume hood. The surface wind speed is only a factor of the performance of the fume hood, and using it alone does not mean that the fume hood is protecting users.

The way to ensure that the fume hood exhausts correctly is to install a pressure gauge to monitor the differential pressure (DP). However, because the DP value is always beating, it is difficult to tell the user which reading value can ensure the pollutant control ability of the exhaust hood. In fact, the ever-changing DP value observed indicates that the exhaust hood can't keep consistent negative pressure difference. Maintaining a certain negative pressure difference is necessary for pollutant control. In order to seek better performance index, the average surface wind speed (wind speed at the entrance of the fume hood) has become the standard index of fume hood performance. The average surface wind speed is more consistent than DP value. It is easy to read, so it is easier to sell products to users.

In the last three years, we have tested more than 400 exhaust cabinets. Many failed the pollutant control test. However, those unqualified fume hoods usually have a specified range of surface wind speed. How can the fume hood run at a speed of 0.4 m/s or 0.5 m/s and still fail to control pollutants? The answer is somewhat complicated. In the 22nd page of ANSI/AIHA Z9.5 for laboratory exhaust standard, it is pointed out: "For decades, the surface wind speed has been used as the main index of the performance of laboratory exhaust hood. However, research shows that a large number of laboratory fume hoods tested involve testing based on pollutant control (such as ANSI/ASHRAE 110, a method for testing the performance of laboratory fume hoods), and only the surface wind speed is not enough to indicate the performance of fume hoods ". What does the surface wind speed mean? In the simplest terms, it tells us that the air is entering the fume hood and is finally exhausted. It tells us that the exhaust system of the laboratory is working normally. This indicates the amount of air sucked into the fume hood. However, the air flowing into the fume hood does not mean what will happen after the air enters the fume hood. What happens in and around the fume hood determines its performance. When testing the function of the exhaust hood (capturing exhaust gas containing dilution), the surface wind speed provides little information about whether the pollutants are properly controlled.

So when you ask most users, "How do you know that your fume hood is safe?" Most of the answers are: "Because our surface wind speed is very good." This is a fallacy. Many people who use fume hoods don't really understand the working principle of fume hoods. There is a lot of wrong information about the fume hood in the market.

Surface wind speed is the wrong index of safety. How did this misunderstanding evolve? For decades, the fume hood was only opened when in use. Each fume hood has its own blower. Therefore, it is important for operators to know that the fume hood is open. The speed alarm is connected to the fume hood lamp. When the user turns on the light, it turns on the alarm. If the exhaust fan is not turned on, a low-speed alarm will be issued. Therefore, having the correct surface wind speed is an indication that the whole ventilation system is running. In the past, most fans were driven by belts. The belt often stretches with use, and the wind machine slows down, thus reducing the surface wind speed. Therefore, the number that can be read on the surface wind speed alarm also indicates the performance of the fan. However, this is different from the performance of the fume hood.

Over the years, this disconnect between the surface wind speed and the performance of the exhaust hood has continued. Just because air flows in the fume hood does not mean that the fume hood is providing safe pollutant control.

Only when the exhaust hood is a real laminar flow device and the air flow is two-dimensional, can the relationship between surface wind speed and pollutant control be effective. However, the airflow in the traditional fume hood is not laminar, and the airflow organization is not two-dimensional. Most fume hoods are very turbulent.