Use, Inspection and Maintenance of Fume Hood

Date: 2022-01-19 Source: RUANQI Classification: Resources

Use, inspection and maintenance of fume hood —— to fume hood users in colleges and universities

Chemical fume hood in laboratory

Fume hood is the main method of exposure control in laboratory. The fume hood is one of the most important ventilation and safety equipment in the laboratory. It is usually ventilated separately from the heating, ventilation and air conditioning (HVAC) system of the building, and no longer circulates into the building. When toxic compounds or compounds with boiling point lower than 120°C are used, a fume hood should be used. When the materials used exceed the exposure limit of the laboratory, the fume hood or other effective local ventilation measures must be used.

The allowable exposure limit criteria include:

● Occupational Safety and Health Administration's allowable exposure limit (OSHA PEL)

● Exposure limits recommended by the National Institute of Occupational Safety and Health (NIOSHRES)

● American government industrial hygienists meeting threshold limit (ACGIHTLVs®)

● American Industrial Hygiene Association Workplace Environmental Exposure Limits (AIHA WEELs)

01 type of fume hood

The types of fume hoods in universities include chemical fume hoods, radioisotope fume hoods and perchloric acid fume hoods, as well as various air flow control devices. The control of fume hood includes constant air volume (CAV) and variable air volume (VAV). Some colleges and universities still keep some old wooden or cement fume hoods.

02 How to use the fume hood

If the fume hood is used correctly, it can provide adequate protection for most laboratory processes. Includes that the operating sliding door of the fume hood must not be higher than the designed opening height. This height is usually marked on the columns on both sides, and the red indicator scissors are usually pasted, as shown in the following figure:

For detailed instructions on the use of fume hood, please refer to the following points for attention:

Training: Personnel who use fume hoods should participate in training provided by schools or specialized training companies;

Verify operation: Before starting work, ensure that the fume hood is in operation. Some new hoods have monitoring devices that indicate acceptable working conditions. If an indication device is lacking, a hand-held anemometer can be used to detect whether there is sufficient surface wind speed. If you do not have an indication device or a hand-held anemometer, try sticking a thin strip of paper on the door handle. By observing the movement of the strip, confirm whether there is a stable exhaust;

Exhaust fan speed: Some older buildings have hoods with two-speed fans. Low speed for ordinary exhaust, high speed for the use of chemicals to provide protection;

Minimize lateral ventilation and eddy currents: The airflow in the fume hood is adversely affected by lateral ventilation and eddy currents. Lateral turbulence occurs when people walk in front of a fume hood or when a window or door near it is opened. Eddy currents are created around the person using the fume hood and around objects inside it. In order to limit these effects, the fume hood should not contain unnecessary objects, and the air wings guiding air flow in the fume hood should not be blocked. The exhaust groove at the rear of the working face is essential for proper air flow. If a large number of devices or a large number of bottles are placed in front of the exhaust tank, they should be propped up or placed on shelves to allow air to flow into the exhaust tank. The device should be placed 15 cm behind the opening of the fume hood. The work should be at least 15 cm inside the opening of the fume hood to prevent interfering airflow and eddy currents, and to avoid pulling polluted air out of the fume hood and into the room; Do not place any beakers, containers for filling chemicals, experimental equipment, etc. within 15 cm from the opening of the cabinet door near the left and right side walls.

Sliding door: The sliding door should be kept as low as possible to improve the overall performance of the fume hood. The more closed the door, the better the protection against accidental chemical reactions. The operation should be carried out at the position where the sliding door reaches the highest designed height or lower. When opening and closing the door, the speed should be slow; When operating practice, hand and body movements as slow as possible. When you need to work before fully opening the hood, you can choose the appropriate protective cover, such as a mask;

Chemical evaporation: It is wrong to evaporate a chemical reaction directly in the fume hood. Any open equipment used in a fume hood that emits large amounts of volatile chemicals should be equipped with a condenser, trap, or scrubber to contain and collect harmful vapors or dust.

Storage: Do not store chemicals or supplies in the fume hood. Chemicals and supplies should be stored in special cabinets.

Flammable liquid vapors: Laboratory fume hoods are designed to reduce flammable vapors below the lower explosive limit when properly operated and maintained. As an extra precaution, use only non-spark-producing and explosion-proof electrical equipment (hot plates, stirring plates, and centrifuges) in the fume hood, where large amounts of flammable liquid vapors may be generated. Be careful with flammable liquids and heat sources.

Containers: All chemical containers must be covered tightly when not in use. One rule is that the container should be open for a few minutes at most (at most), which is the maximum time it usually takes to pour a small amount of the chemical into another container and close the lid. All containers must be labeled with chemical labels and appropriate hazard warning labels (or materials must be used up).

03 Test and inspection of fume hood

Eh&S conducts a functional performance test once a year to ensure that the performance of the fume hood meets the design requirements. If the fume hood fails, it may be necessary to stop using the fume hood until it is repaired. If maintenance is needed, EH&S will notify researchers and put up "Do not use" signs. Depending on the design of the fume hood, the fume hood can be tested with up to five functional performance standards. Include wind speed, smoke visualization, variable air volume (VAV) system performance, noise and pollutant control performance. The specific performance indicators of each test are summarized as follows:

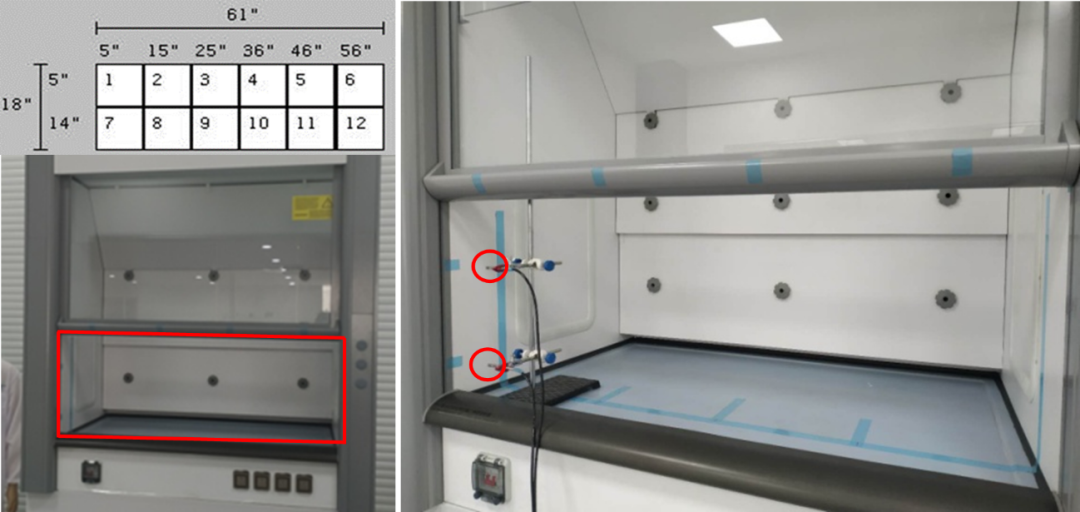

Surface wind speed

—— conventional fume hood: 0.4-0.6 m/s;

—— sliding door height: less than 18 inches;

—— high performance fume hood: 0.3-0.4 m/s.

Surface wind speed test

Smoke visual test

Use a smoke generator to release smoke at the opening and inside of the fume hood, and observe the flow of smoke around and inside the fume hood. Under normal circumstances, smoke can be easily captured by the fume hood and discharged smoothly.

Visual test of smoke

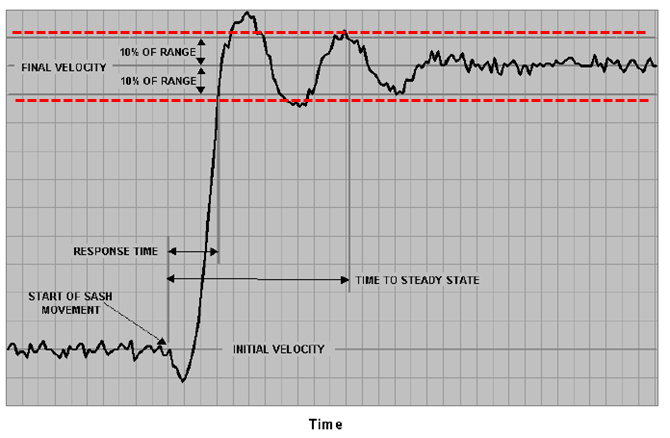

VAV system performance

When the sliding door moves, the VAV control system can respond in time, so that the fume hood can obtain the appropriate surface wind speed. Generally, the response time of VAV valve is not more than 3 seconds.

VAV performance test curve

Noise

Use a sound level meter to measure the noise. The sliding door is located at the working height. The sound level meter is located about 1 foot from the front of the fume hood and 18 inches above the working surface (approximately flush with the ears of the test technician). Environmental sound level must be lower than 80 dBA.

Contaminant control test

SF6 is used as tracer gas to test the overall pollutant control performance of fume hood. Generally, the average detected concentration of SF6 is required to be less than 0.1ppm.

SF6 pollutant control test

04 What you need to know

If laboratory activities may overexpose air pollutants, please use a fume hood or other ventilation control devices, instead of on the desktop.

If the laboratory moves out and carries out some repairs/repairs, the laboratory personnel and researchers should disinfect the fume hood. Please fill in or post the corresponding reminder label or form when purifying the fume hood.

Please always pay attention to whether the ventilation system is turned off. Do not use the fume hood when the ventilation system of the room is turned off.

05 Fume hood alarm

Most fume hoods are equipped with monitors. When the airflow drops to about 80% of the designed speed, the monitors will sound and sometimes give a visual alarm. If the alarm is activated, the following guidelines should be followed:

Make sure you operate the fume hood at or below the arrow of the sliding door. If the alarm still exists, please close the sliding door and wait for a moment, then reopen the sliding door to the working height.

If the alarm continues, please stop using the fume hood, close the sliding door and contact EH&S.

06 Purchase fume hood

EH&S needs help to ensure that the proper fume hood is selected and that the infrastructure of the building can support the installation. Installation and replacement of fume hoods may require prior design and planning. Before authorizing procurement, it is usually necessary to evaluate and design by mechanical engineers (or other qualified parties).